Partners secure significant $50k savings with additive tool

Thermwood recently collaborated with General Atomics to produce a CNC trim tool with a significant cost savings of around $50,000 when compared to traditional methods.

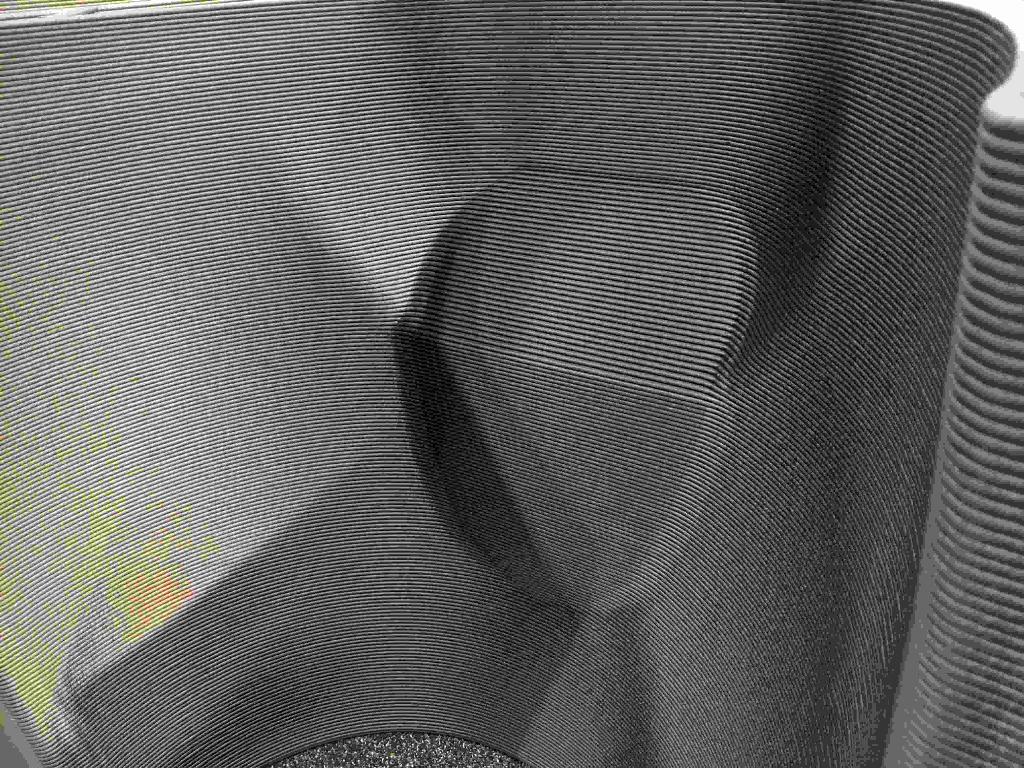

Using a Thermwood LSAM 10'x20', the tool was printed from ABS (20% carbon fibre filled) in 16 hours. Total machining time was 32 hours. The final part weighed 1,190lbs, and represented a cost savings of around $50,000 when compared to traditional methods. Total lead time for the part decreased from 6-8 weeks to less than two weeks by utilising the powerful LSAM system.

Thermwood is a US-based, diversified CNC machinery manufacturer and has also become the technology and market leader in large scale additive manufacturing (LSAM) systems for thermoplastic composite moulds, tooling, patterns and parts with its line of LSAM machines that both 3D print and trim on the same machine.