Carbon composite component and automation innovations at JEC

CompoTech PLUS is exhibiting at JEC World 2022 in Paris, which runs from 3-5 May. The company specialises in providing innovative carbon composite machine tool and automation solutions as an alternative to steel and aluminium to reduce weight, increase stiffness, improve damping and significantly increase productivity, while reducing overall manufacturing costs.

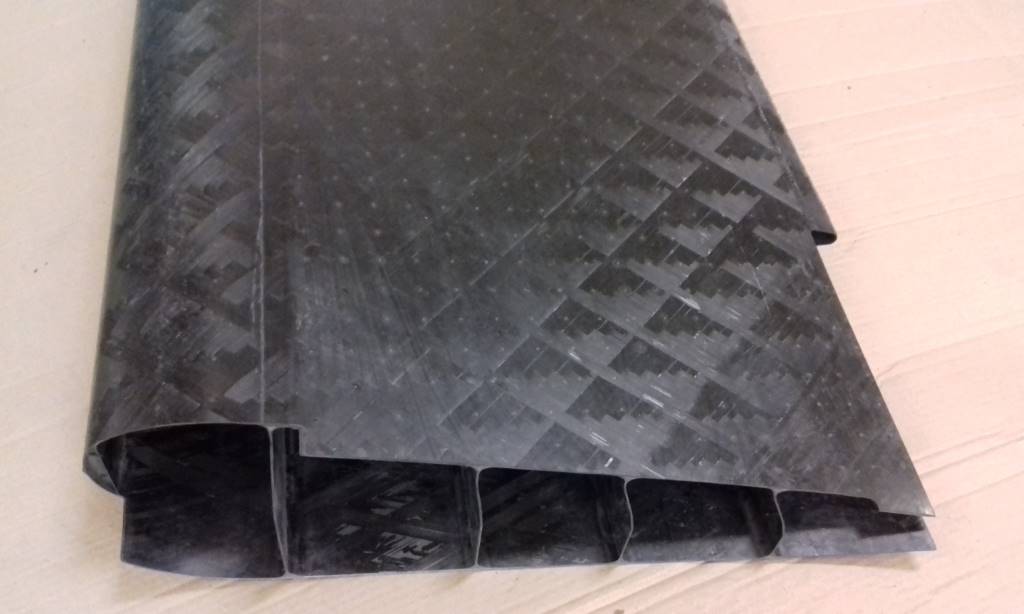

CompoTech has proprietary automated fibre placement production facilities, in-house process development and design engineering expertise, 3D printed tooling and CNC machining. These extensive capabilities enable the Czech Republic headquartered company to create and manufacture to order a wide variety of standard and bespoke lightweight, vibration-damped, carbon fibre epoxy composite components.

The CompoTech team says it applies a fresh thinking composites process approach to finding innovative structural design solutions, with a major R&D focus on improving the performance of automated lines and industrial machines systems.

Latest innovative customer projects being shown at JEC World 2022 include:

- Automated production of a carbon composite Enduro mountain bike frame using integrated loop fibre joint technology (ILT) for stronger, more economical epoxy carbon structural joints.

- New design heavy parts handling industrial robot arm manipulator, designed with high strength ILT joint bushings that connect the CFRP wound tubular arm sections.

- Carbon epoxy composite tubular telescopic mast system. The versatile, high strength telescopic design is currently used in a marine mast application demonstrator for a new concept ‘inflatable’ wing sail, and in the Security sector for mobile police surveillance vehicles.

- JEC World 2019 Aerospace Innovation award-winning carbon composite aileron one-step-cure production technology that requires no secondary bonding, now specified on the Aero L-39NG trainer jet, with production orders for 24 ailerons.

The knowledge and expertise gained from successful process development projects and the production of high precision, dynamic machine and automation systems is transferrable across a wide cross-section of industries, which includes: aerospace, agriculture, defence, automotive, mass transport, bicycles and leisure marine.

CompoTech also offers process technologies that are installed as a complete automated system, with full service and support. Attendees are invited to meet the CompoTech PLUS team during the JEC show.

CompoTech

JEC World (Hall 6, Booth M75)