Making excellence count

With a rich history as one of the UK’s most accredited and trusted composite manufacturers, Atlas Composite Technologies says that put simply, it delivers excellence. Mike Richardson meets with company head of commercial, Ben Swain to hear more.

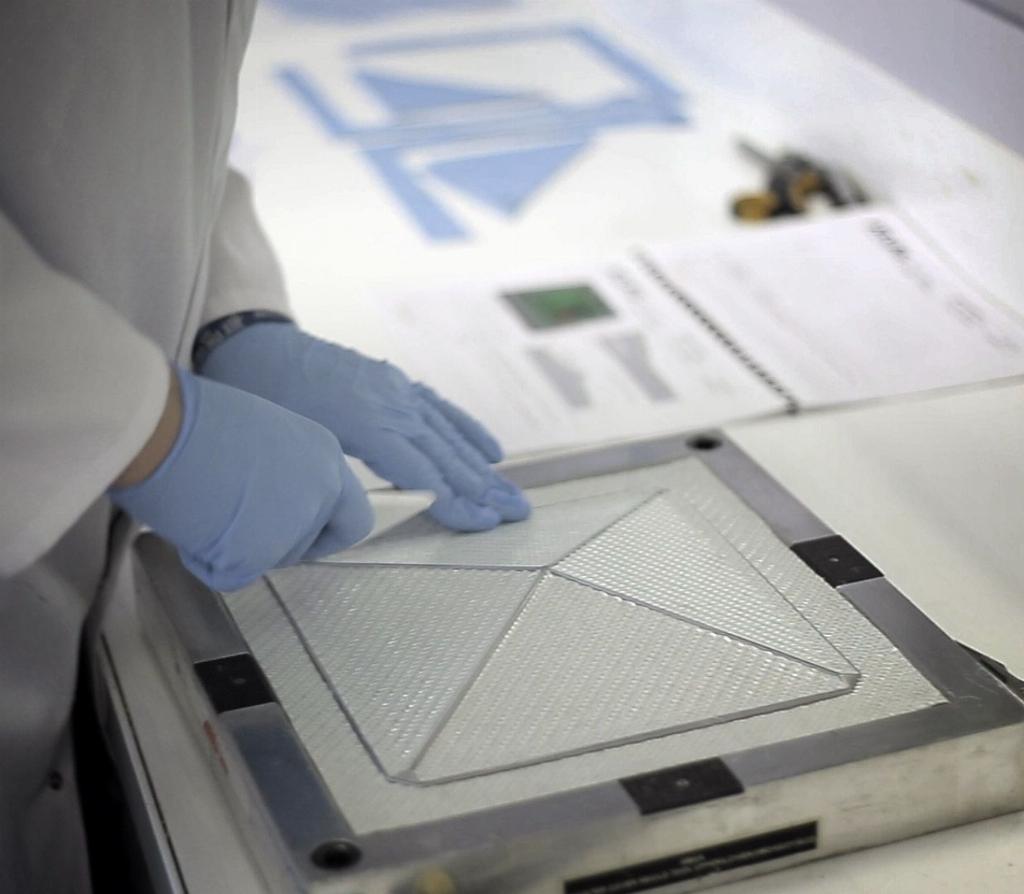

With a workforce of some 140 employees, Ilkeston, Derby-based Atlas Composites Technologies is an AS9100-accredited, self-contained, agile subcontract manufacturer able to take its customers’ basic component CAD files, create all its own internal tooling and fixturing and machine it in-house through to finish parts and assemblies, along with providing very detailed motorsport and aerospace grade inspection facilities and the necessary audit trail that goes with it.

Indeed, with customer orders on the book and a healthy level of experience amongst its staff, Lloyd Pearson as its owner and managing director was savvy enough to realise that Atlas was a going concern when he purchased the company from Senior Aerospace BWT two years ago. With head of sales, Dave Gregory and head of quality in Dave Wakefield in tow, Pearson has reinvigorated pre-existing customer relationships, as well as opened doors to new ones too.

A racing certainty

An example is the company’s Formula 1 subcontract work, which has really begun to motor since Pearson has brought in more people with composite materials experience to instil a really strong team ethic. He has also overseen huge investments in new equipment and the facility itself to the point where it has reached its limits in terms of the building’s capacity - no bad thing, as it demonstrates what Pearson and his charges have achieved in less than two years. Atlas is now looking to relocate to larger premises in order to support its ongoing growth ambitions.

“We’ve grown significantly from an order book of about £300,000 when we first took it on to turnover £8 million last year, and our planned relocation to larger premises will only help to support our growth,” begins company head of commercial, Ben Swain. “We offer a real solution-focused business. We are prepared to take on very challenging projects and we have a really solid base of customers who prefer working with us because they know they can rely on our promise to deliver. We have people here who know what ‘good’ actually looks like – people who have worked with some of the best engineering teams in business.”

In terms of the types of demands placed on Atlas by today’s customers, Swain cites Atlas’ credible capacity and expansion as being among the most important. For some time, businesses have traded on ‘if it comes, we shall build it’, whereas what today’s volume partners want to see is ‘build it, and then we’ll come’.

“They need the assurances that, whilst they know they are dealing with some clever businesses, they also realise that their heads could be on the block if they make the wrong decision. So, there is a bravery element that presents the industry with the decision that if a company hasn’t got a viable premises, capacity and plant in place now – or at least a very clear strategy of how it is going to get there within a suitable timeframe, then it will be very difficult to break into volume manufacturing contracts for some of the higher capacity industries. There is now a requirement to have that personal touch with the customer and what they really want to know is that they’re in safe hands when taking your guidance.”

Completing the circle

Atlas recently purchased a new Antares high-speed 5-axis CNC machine tool from CMS UK and has an Ares machine on delivery too. The company has purchased four new autoclaves and a new Stratasys 3D printer which will soon be producing production structural parts for a Formula 1 client. It has also invested in an RFID tagging infrastructure of manufacturing control software and a huge amount of investment in the infrastructure of materials for the facility in terms of new office space and mezzanines being erected.

“We’ve been running the CMS machines for a number of years because they are really competitively-priced and we’re able to get some positive machining results from them. We enjoy a good relationship with CMS UK, so it was an easy decision to select their equipment. We can all specify the best CNC machine tools going, but it’s about looking at the results we’re getting from the machines we’re using. A machine tool will only do so much; it’s the operator who completes the circle. We’ve got some really good CNC programmers and operators here and as a result, the quality of the patterns that come off the machines are superb.

Atlas’ RFID tagging system is able to track and trace the live movement of components throughout the factory as they progress is seen as a move to the point of harnessing Industry 4.0 and its ‘smart tool’ concepts.

“If you look at the process of machining raw materials into moulds, I can’t see companies like Atlas - who deal with the short life and complexity of products - being able to fully adopt automation to a large degree, because by the time we’ve setup automated robotic cells, the contract has already finished. For the nature of what we are doing, having a highly-skilled reactive workforce is essential for those still relatively low volume jobs that will still have a manual element to them. We’re keen to instil some level of automation to reduce the reliance on that manual element. We want to improve the consistency, without having to rely on high-end expensive resources.”

So, whilst Swain believes that Atlas’ value-add is in its ability to provide the highly challenging, highly technical, often structural parts, it begs the question: what really differentiates Atlas from other subcontracting suppliers and why should a customer choose it over rival companies?

“It comes down to our honesty and integrity - which is based on providing quality engineering solutions and holding hands with the customer to suit their requirements and budgets - and that we are there for them at all times,” he concludes. “The closeness of our customer relationships breeds trust and means that we will always deliver the levels of excellence that our customers have come to expect from us.”