Collaboration driving innovation

PRF Composite Materials’ managing director, Dave Ellson explains how the company’s ongoing facility expansion and product development projects all help to ensure the company continues an upward trajectory.

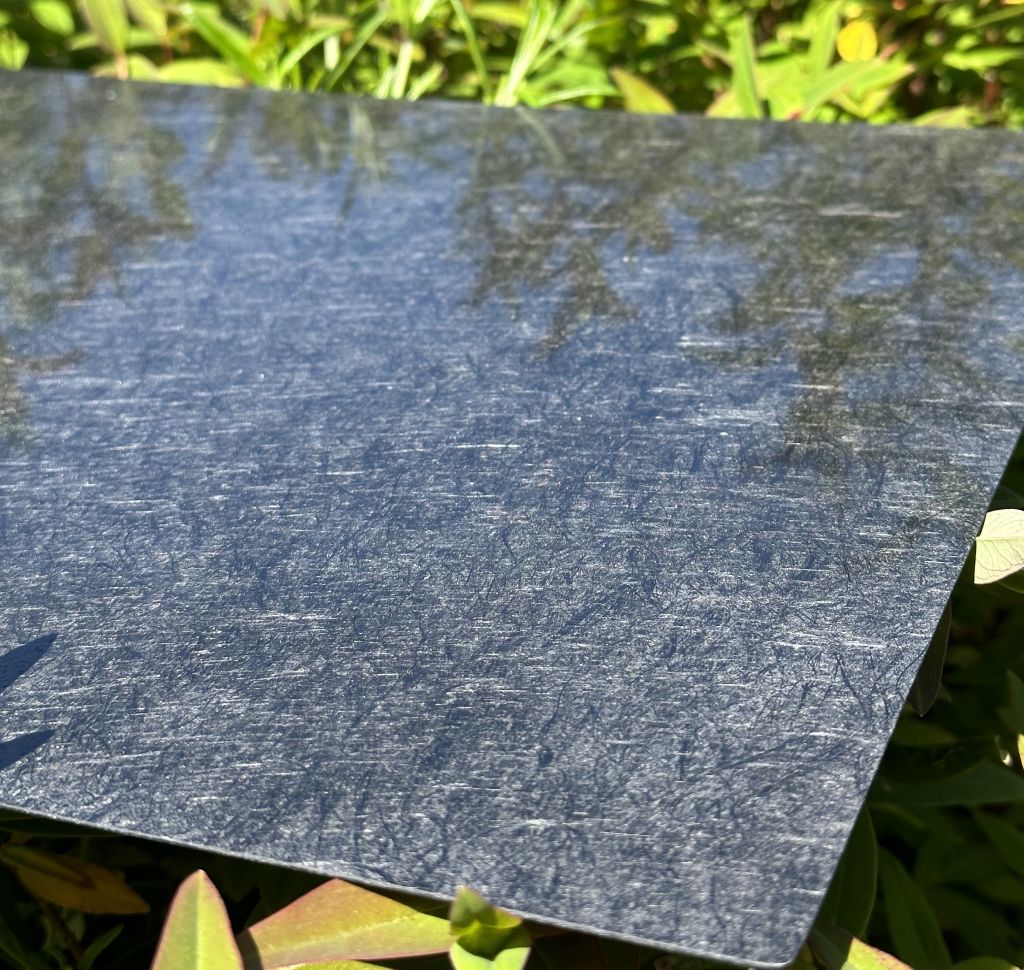

PRF Composite Materials celebrated its 40th anniversary last year by launching both its Q.tool prepreg tooling technology and RP570 FR eXpress cure, its snap cure, fire-retardant prepreg system which is qualified for aircraft interiors. This year, the company has unveiled its recycled carbon prepreg material, REEPREG. Dave Ellson took over the reins of managing director from managing director and founder, Robert Burnell in 2022, with Burnell moving to the role of company CEO.

PRF’s R&D is driven by developing materials that help its customers achieve better quality and significant advantages in cost and time. The company is also looking at how its products can offer improved sustainability. Whilst it recognises the potential that biomaterials have, PRF believes it can do more by finding ways to lower the impact of traditional composite materials and improve their sustainability, whilst retaining their superior composite properties. PRF’s recycled carbon prepreg material, REEPREG has come out of this driving force.

Q) What kinds of demands and challenges are placed on you by your customers?

As always, processing time, cost and technical requirements are a significant driver of our product development. Constructors need materials that take less time to layup, less time to process and the development of our new materials have been driven by this – decreasing time/labour requirements to allow our customers to lower their cost-per-part.

Increasingly, we are seeing the drive for sustainability in the market. Last year, it seemed that this drive was less focused – our customers knew that they needed more sustainable materials, but they weren’t sure what this looked like. Now, specifically with Q.tool, REEPREG and our eXpress cure products, we are seeing the market move towards improved sustainability; maintaining the use of traditional materials for their technical superiority, but focusing on ways that the industry can lower energy consumption, remove waste – particularly plastic and even composite waste for landfill - and improve life cycles and circularity. This has been our focus for some time now, and we are just beginning to be able to quantify the energy savings gained from using our materials.

Q) Please provide any typical examples where your products set you apart from similar competitor offerings?

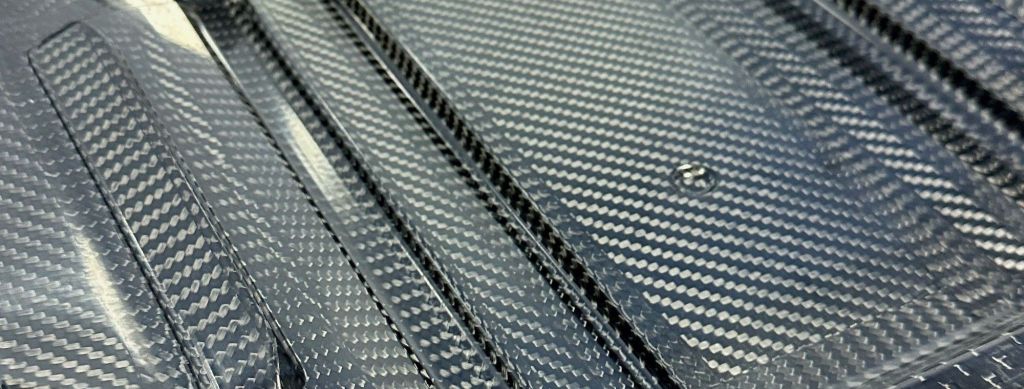

We believe that our latest products – REEPREG, Q.tool and our eXpress cure systems RP570 and RP570 FR are market-leading. I would also add that we are highly experienced in visual quality prepreg, and our kitting service is of the highest quality. We can provide materials cut to our customers’ exact requirements and we can keep kits on stock to be called off as ordered, also helping reduce our customers’ waste.

Q) How much customer hand-holding is required in your product sales process?

Since our beginnings, we have found the best way to develop new products has been taking a problem that a customer is facing, looking at it from all angles, and ‘doing things differently’. This means developing a solution that doesn’t simply copy what is out there, but rethinks the conventional in order to improve the outcome.

Q) Is there a lack of empiric data for companies like PRF to dip into, in the same way that traditional metallics testing companies can access data?

We are fully-equipped to test our prepregs, and have support for industry testing standards including fire-retardancy standards. We are now looking for solutions to measure environmental impact, such as energy consumed in processing for instance.

Q) Is there a concern that less well-developed countries can push unqualified, or at least ‘unknown origin’ materials into the supply chain?

The aerospace industry has major concerns about counterfeit goods ending up in the supply chain, and whilst that is more akin to parts, the same could occur with resin raw materials - as its relatively easy to synthesise resin raw materials to copy but maybe without the same levels of control required. However, with our trusted supplier relationships, this isn’t something that we are overly concerned with in our operations.

Q) Which industries are you seeing the most take-up for your products and services?

We are active across a diverse range of industries, including motorsport and automotive, aerospace, marine, medical, renewables, etc. It’s a real strength of ours that we don’t focus in one area. It allows us to have a significant breadth of experience to offer different customers new products, opportunities and perspectives.

Q) Are you membered into any industry organisations and are they any good?

We are members of Composites UK and the Composites UK Sustainability subgroup. We are working more closely with Composites UK this year. Our marketing director, Hannah Khusainova is on the Advisory Council of the International Composites Summit, organised by Fluency and Composites UK, and we were recently involved in the Tooling for Composites Showcase where we were able to present Q.tool.

Q) Price and on-time delivery are givens, but what else do you see as important to serving your customers these days?

We find that the best results often come when we are working in partnership with our customers to find a solution that suits their skillsets, processing requirements, technical requirements and costs. As mentioned, an increasing need to provide improved sustainability - in not only our materials but also our manufacturing - is becoming a growing factor.

We also look at our customer service from every angle to see where we can provide better solutions for our customers. We have recently implemented our new ‘Fast to Freeze’ manufacturing protocol, which we developed to minimise the time our prepreg tiles are at room temperature in our facilities. We heard from the industry that constructors were experiencing compromised out-life when rolls were cut into tiles, with the cutting process losing up to one day of out-life. We can now manufacture prepreg, cut and freeze tiles typically within one hour – significantly preserving the out-life for our customers.

We have also made a significant effort to minimise plastic consumables in our processing. We are now saving over 50% of the plastic consumables we would have previously used in manufacturing, and 99% of our consumable plastics are now recyclable. We are looking at ways to minimise cardboard usage and waste, using a new and reusable wooden crating system with our customers calling prepreg materials off stock. Lastly, I think there is much to be said about trust and integrity. We hold integrity highly as a core value of our business and I would like to think that we are known in the industry for this.

Q) What do you feel are the most important assets of a company?

In a technological industry, technology is obviously important but when we are developing technology, without delivering and servicing that technology, there is little value for the customer. As a customer-focused company, PRF listens to the needs of our customers, beyond just technology. That requires developing relationships and building trust; trust that the customer can give us the information required, without risk of compromising IP, and trust that PRF will deliver in all aspects required.

Q) What differentiates your company from the competition?

We developed the phrase ‘Doing things differently’ to encapsulate our approach, particularly to working with our customer and our product development. We look at the problem and what is available on the market, and the outcomes we are aiming to achieve with a new product, and then we set about product development. This is based on creating a new product that achieves the outcomes we set in place – which are set by the market need – rather than imitating and simply bettering what is already available on the market.

Q) Is there a particular success story you can shout about involving a satisfied customer?

We have worked with many customers over the years, the majority of which we must maintain confidential. However, one customer had a requirement for high volume production using a carbon prepreg that needed to meet the rigorous FST requirements of the aerospace sector. As such, we developed a fire-retardant version of our RP570 to deliver a material that enabled them to achieve the necessary production rate, alongside their quality and technical requirements.

We have also recently worked with Piran Advanced Composites – a company that has selected our Q.tool for a large scale tooling project that they are working on for a major aerospace application. Q.tool has been important to this project in speeding up their tool construction, and they have achieved great results with this new tooling technology.

Q) Finally, where to next for your company?

We will continue to invest in innovative product development, providing materials to the market that bring value to our customers, with a focus on improved sustainability – with real impact – and cost reduction. We will continue to invest and expand the business to ensure that we are ready to meet the next challenges that the industry will face as composites develop into new areas of application. We have and always will work closely with our customers and value good relationships with our suppliers that are built on honesty and integrity.