Cleanrooms under the microscope

Joe Govier, founder and managing director of industry leading cleanroom manufacturer, Connect 2 Cleanrooms examines the art of creating a repeatable composite production environment.

Today’s composite parts need to be predictable in performance and their engineering properties. Reducing variability in the layup process of prepreg manufacture leads to a more reliable and consistent product, improving yield. The sister industry of polymer processing, has been using statistical process control (SPC) techniques to control variables in the manufacturing environment for over two decades – pushing design and application boundaries.

To create environmental control, we first need to understand the main variables: airborne particulate, air temperature and humidity and people.

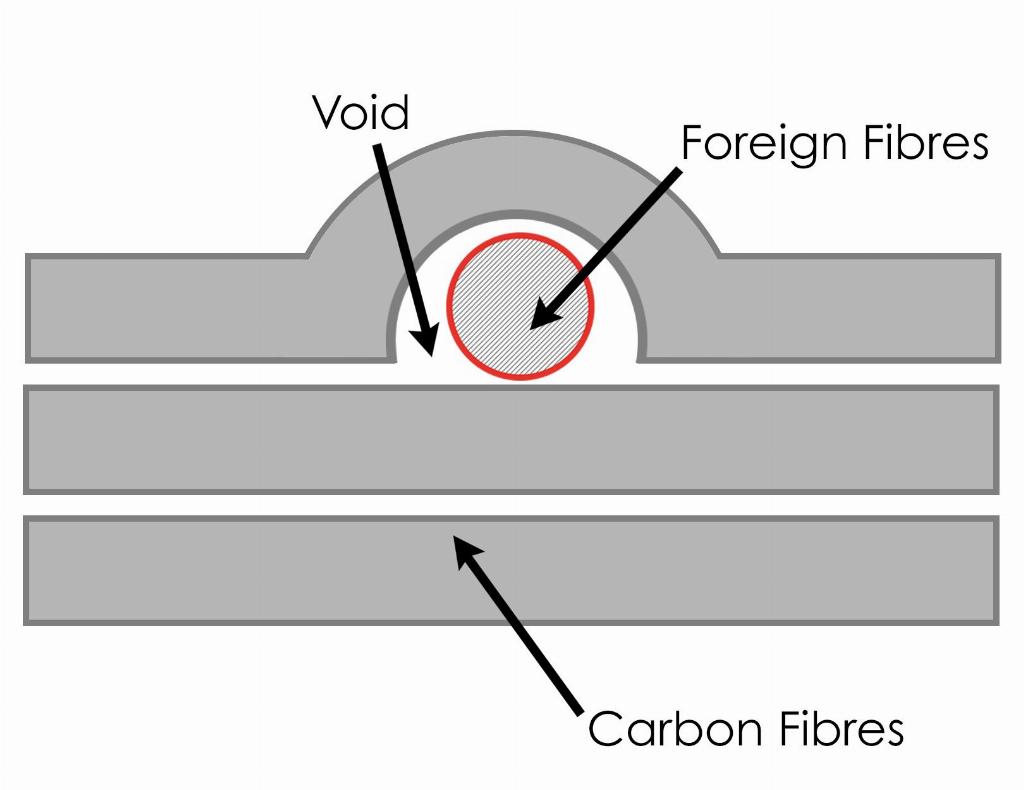

During the prepreg laying up process, any elements of contamination, such as foreign fibres, could create a peak in the laminate, surrounded by a void - preventing the layers from lying flat. Although minute in size, these peaks and voids could create a point of weakness within the laminate, leaving the part open to such risks as an ingress of moisture.

The risk here is that the point of weakness can ultimately turn into a point of failure, causing delamination. When we consider the critical applications for composite parts, we get to appreciate the essential need for contamination control and how the environment is very much a variable in the process.

For parts that are consistent and repeatable, the environment must be consistent and repeatable. If the layup process is being conducted in a controlled cleanroom environment, the risk of particulate contamination will be significantly reduced, as will the risk of delamination later in the process life.

The ISO Clearoom Standard defines a cleanroom as - a “room within which the number concentration of airborne particles is controlled and classified, and which is designed, constructed and operated in a manner to control the introduction, generation and retention of particles inside the room”.

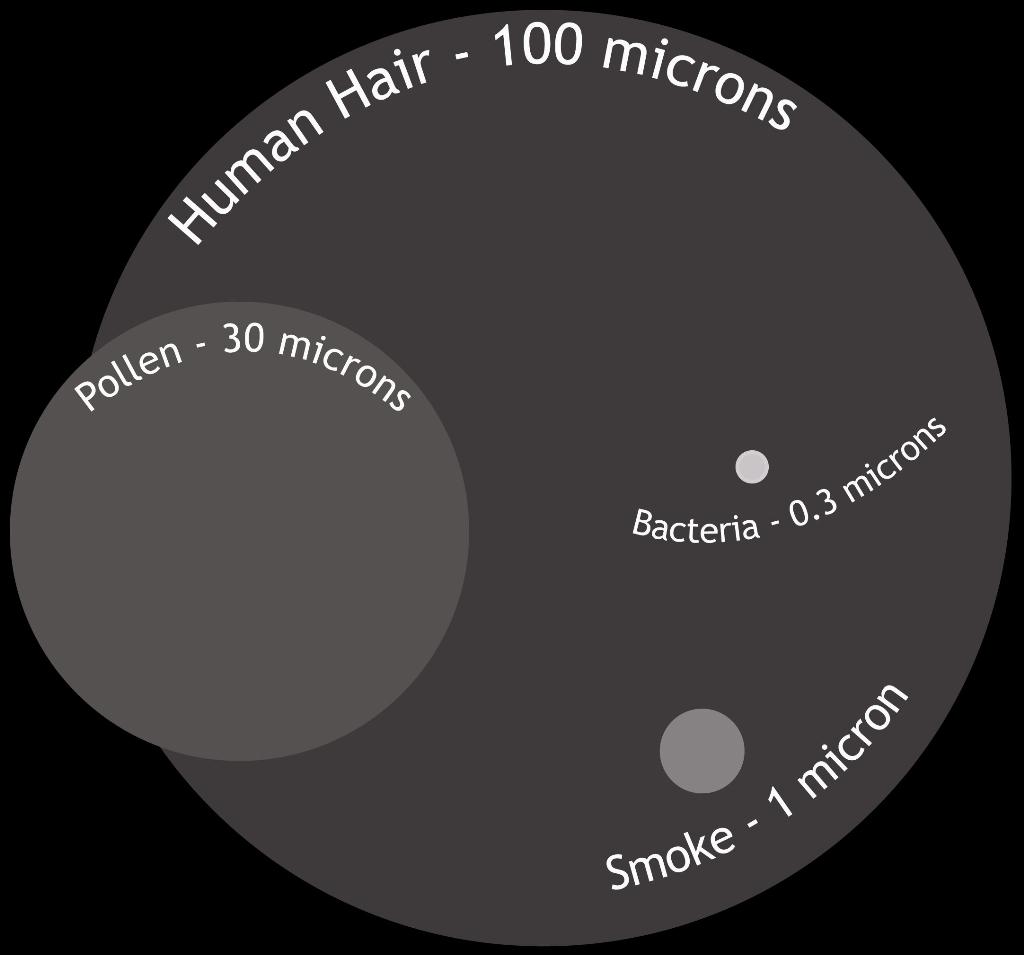

HEPA filtration in cleanrooms are 99.99% efficient at filtering out particles down to 0.3µm, which is one hundredth of the size of the average pollen particle.

Given this microscopic level of environmental control, a classified clean environment can be a huge driver for creating a controlled and repeatable environment for the production of mission critical components.

But organisations need not worry about where to build a purpose-built cleanroom facility. A cleanroom can be designed and built in existing production facilities, even around existing machinery if required. This means the disruption to production can be kept to a minimum whilst being upgraded to be ISO 14644-1:2015 classified.

A reputable cleanroom company will be able to advise on the levels of air changes and particulate limits you will need to adhere to when meeting your ISO 14644-1:2015 class.

With digital advances in cleanroom control, there are opportunities to make finer incremental differences to give a greater level of control.

Composite components often face a 100% inspection rate to identify faults. As faults could be integral, methods of inspection need specialist equipment; often using a combination of contract measurement machines, vision systems, x-rays, weights and other methods.

This means inspection can be a lengthy process, not to mention destructive and wasteful; as the thermoset parts are non-recyclable, so high failure rates are expensive to an organisation.

Composites sister industry, injection moulding and thermoforming plastics, faced similar challenges. But with the widely adopted increased control over environmental parameters, through cleanroom manufacturing, many organisations now rely on SPC techniques. The reduction in environmental variables allows organisations to inspect a lower volume of parts, as they have a higher confidence in the output of a part.

Setting the control

The European Aviation Safety Agency advises that cleanrooms should be “operationally controlled in terms of temperature and humidity”. As temperature and humidity are variables which affect composite parts, this will help create a stable and repeatable environment.

If a cleanroom has been installed in an area which is already temperature and humidity controlled, the cleanroom will draw from this processed air and filter the airborne particulate.

However, if the cleanroom needs localised control, air handling can be provided through local air conditioning units which process air then feed the cleanroom’s fan filter units with the cooled air. This method is often preferred to commissioning an air handling unit (AHU), as there is a lower initial investment plus lower ongoing costs due to it being a more energy efficient approach.

People as a variable

The quality of raw materials and tolerances are able to be controlled through supply chain and process management. People, however, are a variable in terms of application and environment.

With regards to application, the operators who are handling the laying up process can all affect the output. How they handle the materials, including the speed and the pressure they apply, are all variable factors.

The development of robotics in the industry, allows for a more consistent and repeatable approach. The challenge lies in creating the dexterity which human operators give – for which there are artificial intelligence (AI) research and trials in place at the National Composites Centre.

There trials are generating excitement in the industry, as automation can allow organisations to increase volume, give greater tolerances and reduce variables.

Although the use of robotics is growing in the composite field, many organisations will still rely on operators for manufacture - and with people, comes a contamination risk.

Clothing and behaviour

People are often cited as the largest source of contamination within a cleanroom and a statistic from Cleanroom Technology states that “people can, when walking, produce about 1,000,000 particles ≥0.5µm and several thousand microbe-carrying particles per minute”.

If an organisation has invested in a cleanroom environment to give submicron filtration, the operatives which are working within that environment will need to adhere to protocols which will minimise the contamination risk they pose within that environment.

These protocols typically include wearing non-shedding clothing and behaving in a way to minimise turbulence within the cleanroom.

When considering clothing, a simple white garment may look clean, but remember we are dealing with microscopic particles. The material and construction will need to be considered.

Material should be low-linting, such as a spun bonded polyethene, non-woven material. With the construction, consider potential leakage points, such as stitched seams, and choose a garment which offers a solution to these common pitfalls, such as interlocked or bound seams.

The European Aviation Safety Agency recommends the use of “appropriate gloves” to “prevent contamination of Prepreg materials and film adhesives during handling (e.g. skin oil)”. The particulate levels should also be considered. Cleanroom compatible gloves are often washed in filtered water to remove any excess particles and packaged in plastic rather than high linting cardboard.

With advancements in cleanroom technology and automation, the composites industry is in a transitional stage, journeying towards greater process control through repeatability. This in turn will bring new applications and growth for organisations that embrace the development.

References:

- Cleanroom Technology: Fundamentals of Design, Testing and Operation, Author: W.Whyte, Copyright 2001 John Wiley & Sons Ltd.

- BS EN ISO 14644-1:2015 Cleanrooms and associated controlled environments - Part 1: Classification of air cleanliness by particle concentration.

- European Aviation Safety Agency (UG.CAO.00135-003 Foreign Part-145 Approvals – Composite Repair Workshop)