All in it together

Mike Richardson journeys to DK Holdings’ Staplehurst, Kent facility to meet with sales & marketing manager John Emptage and hear how the company intends to celebrate its 65th anniversary in the composites industry.

What first strikes you when you walk around diamond tooling specialist, DK Holdings’ facility is just how ‘together’ everything is. Located practically in the middle of the middle of Kent, the company’s shopfloor links seemingly diverse production processes - like electroplating and resin bonding - with traditional machine tool shopfloor practices. As John and the company’s marketing assistant, Julia Loeser take me on a plant tour, it’s a real pleasure to witness the design and manufacture of bespoke diamond tooling, firsthand. Clearly, DK Holdings and its team of employees are all in this together.

According to John, DK Holdings continued to invest in both machinery and the team in 2023 to fulfil increasing customer demand in its diamond tooling range. The company installed an additional 585 solar panels on one of its production halls which now enables it to produce at least 33% of the energy required to run the site annually via solar power. Investment in machinery is driven by customer demand with one of the company’s latest acquisitions being the installation of a BOY 90E injection moulding machine.

So, with huge congratulations to DK Holdings on reaching its 65th anniversary, I begin by asking John what the company has planned to celebrate this milestone?

“We are proud to have been working with our partners in the composites sector from the word go in 1959,” he begins. “To celebrate this major milestone, our marketing team introduced our #dk65 hashtag as well as our 65th anniversary logo across our social media channels, updated our catalogues across the range and we are rebranding our website which is due to launch very soon.

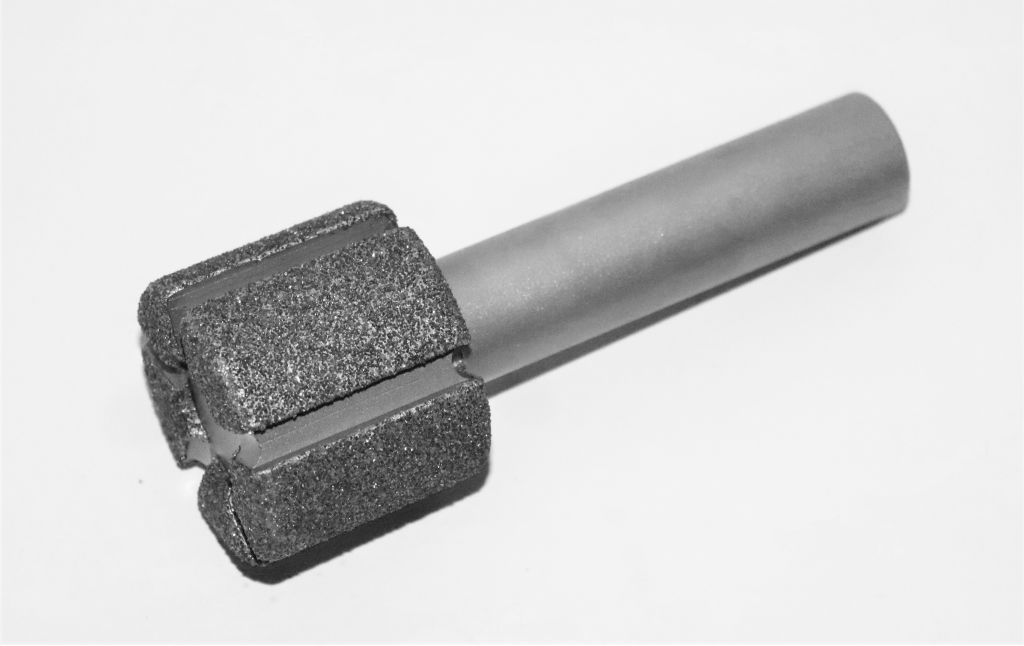

“We could not have weathered the challenges of recent years without our business mantra ‘Working in Partnership’. We can supply off-the-shelf solutions for cutting, grinding and drilling of composite materials, but our real passion is in the design, manufacture and supply of bespoke tooling solutions. Whether it is to enable a customer in the wind turbine blade manufacturing sector to economically cut GRP material, or supply a bespoke electroplated diamond holesaw that can cut through thick material – our engineers can always help. We are also lucky to have a fantastic technical support team who are always on hand to answer customer queries or work on sample material to suggest a solution best suited to individual needs.”

Multi-tool solutions

John says that demand for bespoke Diamond Tooling across the composite sector remains high with companies looking to find cost-effective ways to streamline production processes. He also finds that many customers are increasingly looking for more ‘multi-tool’ solutions that can do two jobs in one to be more cost-effective from a tooling and production process perspective.

“Our range of diamond tools can be used across any sector that cuts, drills, chamfers, grinds and polishes composite components,” he continues. “Through manufacturing from our ISO-accredited facilities in the UK, we can virtually make any tool you need. We work with companies in aerospace, motorsport and – particularly in export – GRP/FRP composite pipe manufacturers who utilise our electroplated diamond tools for cutting, grinding and chamfering processes. Most fascinating are the continuous changes in composite materials – with natural fibres still being one we see more and more when customers ask us for a solution and provide samples.”

I’m interested to know whether the company is looking to discover new markets and countries this year – and how these opportunities will be achieved. According to John, the company continues to expand its export activities with sales now accounting for approximately 40% of annual turnover.

“Visiting tradeshows such as JEC enables us to introduce our diamond tooling range to untapped markets and sectors, and we are looking forward to being a part of the show again this year via the Composites UK Pavilion where we have a corner plot with a meeting area. Face to face conversations are important to us as we always strive to fully understand a requirement that’s presented to us.

“Tradeshows are also vital when meeting with new and existing partners around the globe. Having that sit-down conversation enables us to fully understand requirements and more often than not, there and then suggest a solution that might even do the job quicker or more precisely. Visiting shows such as Farnborough Airshow and Advanced Engineering UK have gained more importance in recent years which is very clear when you consider that the Composites Forum at Advanced Engineering UK was extremely busy. The composites sector remains an exciting one to be in with all its developments and innovation, it’s great to be a part of it!”

Whilst the composites sector may well be an exciting one to be part of, it also comes with a variety of never-ending technological barriers to overcome. Never a dull moment, so just how does DK get its diamond tooling products to market?

“It really varies from sector to sector. We can be involved as early as the machine building stage for a brand new process, from liaising with the machine builders to ensure their machines are capable of running to the correct parameters for diamond tools to work efficiently, to working with customers who already have machinery, but want to machine a different composite material or want to improve their processes.

“Our vast knowledge and ability to manufacture bespoke diamond tooling enables us to deliver continued support to our partners at every stage. For our team of experts, every day is a school day as we learn and evolve with our customers’ demands, which makes it so fascinating and enjoyable.”

Hard work pays off

Sheer hard work and dedication has seen DK Holdings’ compliance team achieve a number of milestones in 2023, namely ISO9001:215 Quality Management and ISO45001:215 Health and Safety Management UKAS accreditations with the British Assessment Bureau. Additionally, the company achieved EcoVadis Silver Medal status, an accolade which means that it is now in the top 18% of companies undertaking the survey in 2022/23. DK has also worked with Composites UK member companies for a number of years, meeting up at tradeshows and other networking events.

“In 2023 we officially joined, which not only allows us to exhibit at JEC World via their pavilion, but also enables us to understand upcoming R&D projects in this innovative sector. In a nutshell, they are invaluable ambassadors for UK manufacturing as a whole and the composite sector in particular. There is a lot these organisations do as a whole and we are grateful for their support.”

When it comes to differentiating itself from the competition, John is keen to stress the company’s ‘Working in Partnership’ mantra.

“It’s not just a slogan we use in our media campaigns - we truly do and have worked in partnership since our humble beginnings in 1959. We do of course have off-the-shelf products in the range, such as our electroplated diamond blades which are hugely popular in the wind turbine blade sector to our electroplated routers used in the motorsport industry.

“When it comes to developing a bespoke solution, we can either work from a sketch, CAD drawing or by testing tooling on the sample material provided. Our production facilities now span 4,000m2 and include manual, semi-automatic and CNC lathes, milling and grinding machines. Combined with our knowledgeable team of production engineers and we have the perfect mix to design, manufacture and supply a diamond tooling solution truly up to the job.”

John agrees that often, the most important assets of a company can be a combination of many things: a defined strategy, its people, its experience, its use of technology and its location.

“We continuously strive to invest in both our machinery and people to ensure we can fulfil customers’ demands for precision diamond tooling solutions that satisfy their requirements. When it comes to location, I am proud to be part of the UK manufacturing sector and it was encouraging to see that in 2023 we climbed back up to 8th place in the world rankings (analysis published by Make UK in September 2023). A recent survey by Make UK published in January also made for encouraging reading with confidence growing in the sector, despite the ongoing challenges.”

Equally encouraging must be DK Holdings’ long-standing partnerships with customers and suppliers, as they can often lead to a better way forward for all concerned.

“Our partnerships with customers and suppliers are built on trust, which I think is vital when you want to be successful in your field and build a business that weathers all sorts of economic conditions - another reason why we are celebrating a 65th anniversary this year,” John concludes. “I’d also include research centres here. We work with a number of R&D facilities to ensure our diamond tools continue to set the standard and support composite component manufacturers in the best possible way.”

Clearly, DK Holdings is all set for an exciting year ahead, with lots in the pipeline and the odd celebration thrown in too. If you are attending JEC World in Paris, visit the company located in hall 6, stand S62/T62, raise a toast together and celebrate 65 years of precision diamond tooling for the composite industry at Composite UK’s Pavilion.