A big circle of composite solutions

Composites in Manufacturing previews some of the companies demonstrating their latest products and services at this year’s JEC World.

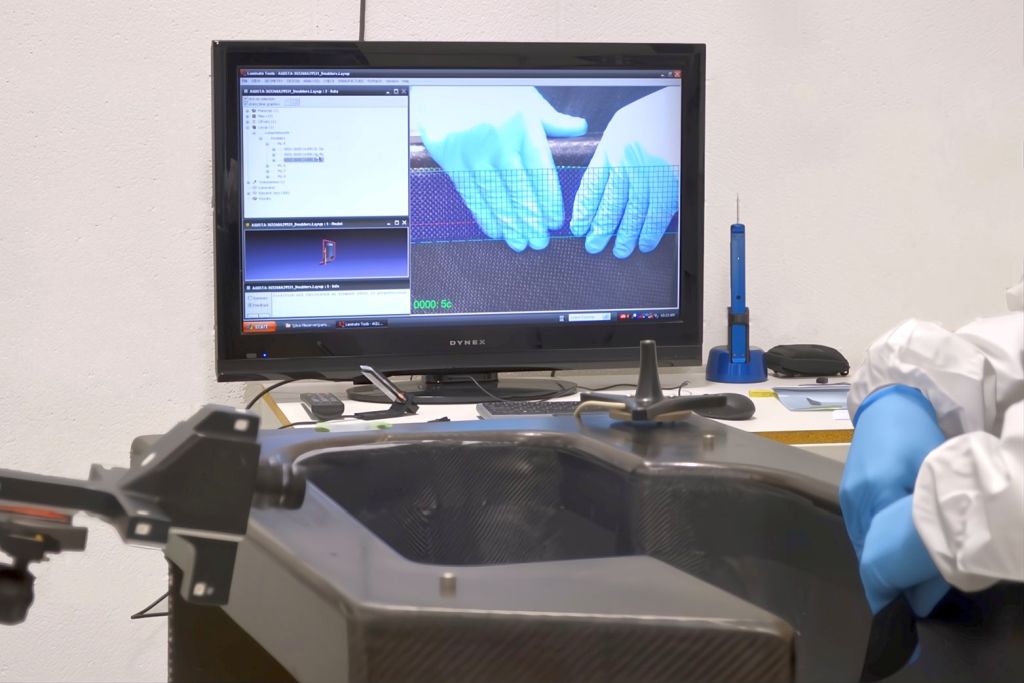

We begin our exhibitor round-up with Anaglyph (hall 6, stand D86). The UK composites design and manufacturing solutions specialist, will demonstrate the latest version of its hand-layup ply placement technology, PlyMatch at the event.

PlyMatch uses augmented reality (AR) to show the live combined images of actual and target ply outlines and fibre orientation details on a monitor, so that the two can be matched by the operator.

PlyMatch is used for the accurate placement of plies in hand lay-up manufacture of composite parts, as well as for monitoring and validation of automated methods. It is particularly useful in case of complex geometries, with high curvature or enclosed spaces. PlyMatch is used by manufacturers in many sectors at this stage.

COMPCUT (hall 6, stand R89), the specialist division of cutting and machining solutions, powered by Sharp & Tappin returns to JEC. The company will demonstrate both its ACS 300 saw and its PCR 300 router from its stand.

The ACS 300 - the smallest of COMPCUT’s range - offers a 300 x 300mm clear panel size which is ideally suited for producing test specimens, providing consistent and accurate parallelism and perpendicularity down to 0.03mm. The finish of the machined test samples requires no post-processing, which makes these machines an obvious choice for R&D and test centres.

The PCR 300 offers a ‘hybrid’ machining solution combining both routing and CNC milling, capable of cutting high precision ‘dog bone’ and ‘open hole’ compression test samples from an increasingly diverse range of composite materials. The PCR 300 Router is available as a ‘complete solution package’ with a range of cutting tools plus a suite of machining programmes (application dependent), making it quick and easy to operate.

JEC attendees are invited to bring their own composite materials with them to the show and witness first-hand the capabilities of COMPCUT’s cut quality and accuracy.

Elsewhere, Composites UK (hall 6, stands S62/T62) is once again organising the UK Pavilion for the third time in as many years. The UK Pavilion will comprise two adjacent stands and house over 20 companies. Among those exhibiting are DK Holdings, the National Composites Centre, Advanced Engineering Show, C&J Antich, CiMCOMP, CNC Robotics, Dolphitech, Hive Composites, Hypetex, Leading Edge Strategy Consulting, Loop Technology, Plyable, Slack and Parr and TWI.

As mentioned, Composites UK member company, DK Holdings, an ISO-accredited manufacturer of precision diamond tooling will be exhibiting on the UK pavilion stand.

“We are excited to be back at JEC World in 2024,” states company sales & marketing manager, John Emptage. “Face-to-face networking with our global partners in the composites industry is vital as it enables us to understand their requirements and develop diamond tooling solutions to optimise production processes as well as assisting with new projects.

“You’ll find us at Composites UK’s Pavilion for the first time since becoming members earlier this year which we are very much looking forward to. Attending as part of the UK trade community for the composite sector enables us to work with our fellow members exhibiting and share what innovative projects we have in the pipeline for our 65th anniversary year. Come and meet the team in Paris in March 2024 – we are looking forward to seeing everyone there.”

Moving on, PRF Composite Materials (hall 5, stand E57) will be bringing its innovative prepreg materials and new adhesives and primer films to JEC World this year. The PRF team will be showcasing a new suite of resin films, including the new RFA570 eXpress cure, a fast-curing epoxy film adhesive designed to provide structural bonds in honeycomb and composite bonding applications with a 4 minute cure at 140°C.

The team is also celebrating Q.tool prepreg tooling technology, which has recently been awarded a UK patent. Offering a faster option to the traditional 1:8:1 tooling, Q.tool’s prepreg fabric architecture produces a highly drapeable material, excellent surface finish and provides a saving of 50% of the layup time of a conventional 1:8:1 system and debulks reduced to as few as one.

The team will also have aerospace components on display constructed using the company’s RP570 FR eXpress cure epoxy prepreg system. Formulated for structural components requiring FST properties, RP570 FR is a fire-retardant ultra-fast prepreg system which is cured and demouldable after 5 minutes at 160°C.

Meanwhile, Roth Composite Machinery (hall 5, stand J02) will be at JEC World with an international team of experts from Germany, the US and Korea to present its portfolio of services, as well as its latest innovations. The company has invited software company, mefex as a co-exhibitor on its stand.

“Our joint presence at the trade fair will enable all interested parties to learn about the advantages and possibilities of the automation software in all its aspects,” says Andreas Reimann, managing director of Roth Composite Machinery. “We are looking forward to interesting discussions because it is precisely this interaction that provides important impulses for future developments which we, as recognised filament winding experts, are actively shaping.”

Next up is Thermwood, who will be LIVE printing an autoclave-capable tool for composite layup of an aircraft engine air inlet duct on an LSAM Additive Printer 510 in the LIVE Demo Area located in hall 6 at the show. The company will print a new tool each day with material from a different material supplier.

In addition to LIVE printing throughout the day, Thermwood will also present an interactive demonstration once per day that will allow participants to see a real-world application of creating high-temp tooling with an LSAM system.

This live demonstration will help bridge the gap between theory and practical application and help understand the full potential of LSAM and how it can help enhance productivity and innovation. Thermwood will also have its regular booth staffed by its sales team in hall 6, stand P52.

Finally, Zünd (hall 5, stand S57) will be on hand as a leading provider of complete solutions for digital cutting in the composites industry. Visitors will have the opportunity to get a close-up view of how data management, cutting and assembly can be intelligently digitalised, automated and streamlined. Digital production cells offer particularly large cost reductions in materials and personnel. Zünd uses two practical examples to demonstrate how such digital production workflows for cutting composites can be structured.

One production line illustrates how easy it is to integrate a robot and its functions and fully automate the removal and sorting of parts. The robot arm is controlled by the ZCC Zünd Cut Centre operating software via the Pick&Place Interface. Thanks to central control via the ZCC, cuts of any shape can be removed and individually sorted in a flexible manner by the Zünd G3 Cutter. If the cut parts are removed by hand, the operator can mark each part with labels with printed barcodes and job information, with visual support provided via a projector. The required parameters are derived from the job metadata.

On a second production line, the focus is on maximum material utilisation while cutting fibre-reinforced composite materials. This is made possible by a fully digital workflow. The Zünd PreCut Centre – ZPC software plays a key role in the process. In particular, the ability to integrate selected metadata in the output file and transfer it to the finished cut parts via inkjet printers and label printers enables efficient and flawless kitting as well as end-to-end traceability.