Zund to showcase new products at AE UK show

Zund (stand S70) will showcase many new products and features at the Advanced Engineering show, held at the Birmingham NEC from 3-4 November.

Zund's PreCut Center (ZPC) lets you create nested job files simply and efficiently. ZPC facilitates data preparation and output. In just a few steps, users can create fully nested job files and automate their data workflow according to their individual requirements.

The Zund Connect monitoring tool helps users recognise potential areas for optimising the digital cutting process. Zund Connect compiles production data from integrated cutting systems into meaningful key performance indicators, such as cutter capacity, availability, and overall equipment effectiveness.

The Zund Cut Center (ZCC) Visualising Option has been developed to simplify the traceability of cut parts as well as their identification and sorting after contour cutting. The Visualising Option allows the ZCC to use metadata from job and production information in a variety of ways. A projection system above the cutter shows the operator which cut pieces belong together in different colours. It can also indicate on which cut pieces labels must be applied for later identification.

Zund says you can mount the Leibinger Jet 3 inkjet printer on your Zund G3 cutter like any other tool and mark the cut parts automatically. The information to be printed must be available in the ZCC as a text label within the CAD file and can be supplemented with standard text, QR/data matrix/barcode and variable data such as date, time or file name.

Zund UK will also be showcasing live demonstrations of two more new products at the Advanced Engineering show:

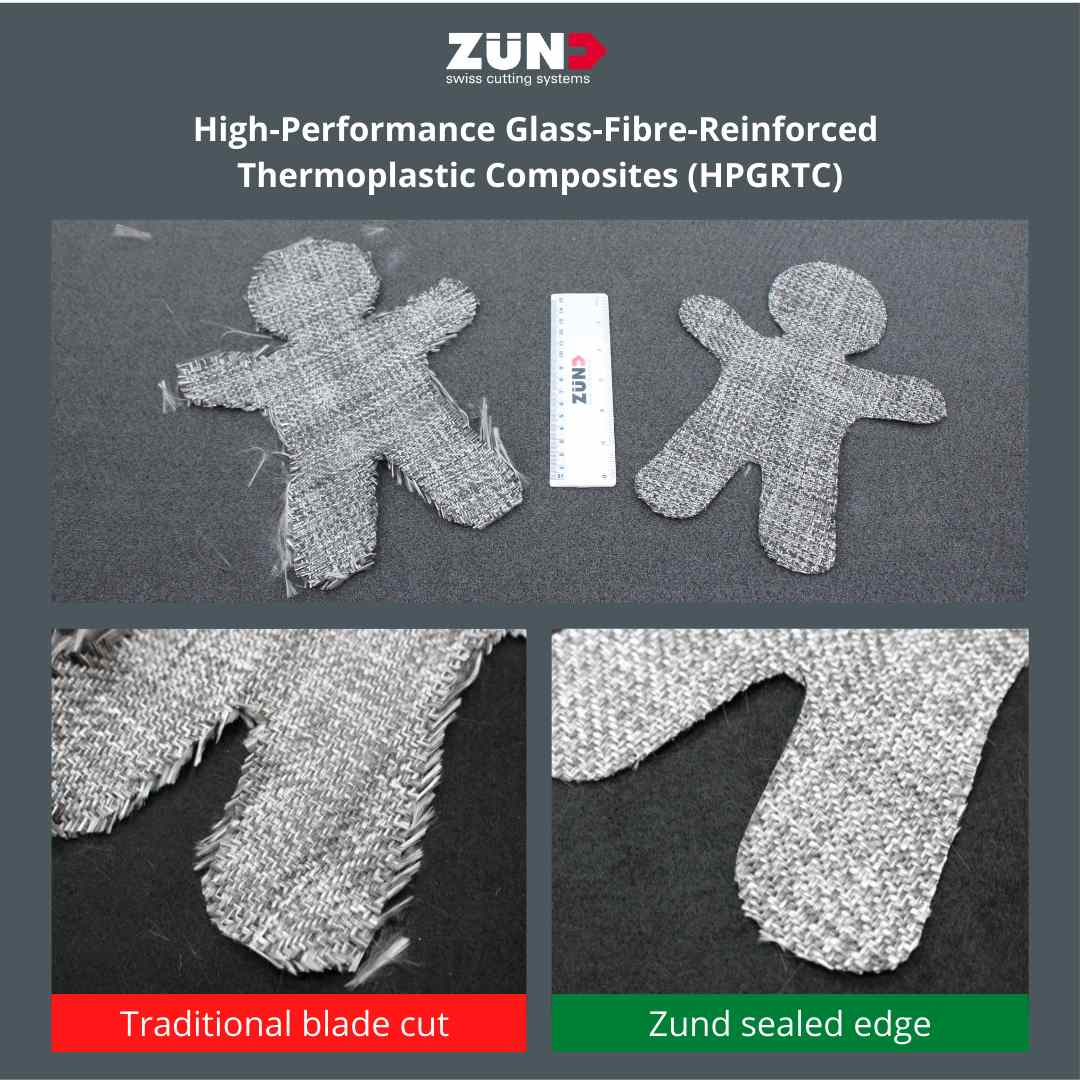

Product 1 - Zund UK has developed a tool to avoid material fraying, loose fibres cross-contamination and part distortion, for customers in the composite industry processing High-Performance Glass-Fibre Reinforced Thermoplastic Composite (HPGRTC).

Its new cutting tool is said to offer a perfect sealed edge finish and both the cutting and subsequent processes benefit from ease of handling parts and a clean and cross-contamination-free environment.

Product 2 - The Hole Removal Tool (HRT) is an innovatively designed solution to remove thicker, heavier, porous waste materials.

The tool automatically removes debris without any operator intervention by simply utilising a special needle tool to pierce and retain the waste material cut-offs that otherwise need to be removed manually.

Grab your free ticket and join Zund on stand S70 in hall 3A.