The cut and thrust of flatbeds

Looking for digital flatbed cutting solutions? Then look no further than Zünd. In a Q&A session with UK sales & marketing manager, Dean Ashworth, Mike Richardson hears how the modularity of the machines and a wealth of options, ensure there is a Zünd system that suits anybody looking to do digital cutting.

Looking for digital flatbed cutting solutions? Then look no further than Zünd. In a Q&A session with UK sales & marketing manager, Dean Ashworth, Mike Richardson hears how the modularity of the machines and a wealth of options, ensure there is a Zünd system that suits anybody looking to do digital cutting.

Zünd UK has been supplying Zünd cutting tables since 1993 as an independent reseller to Zünd Systemtechnik. Over the years, the company has gained experience of many different markets and in 2017 it was acquired by Zünd Systemtechnik to become part of the global Zünd family.

Q) In light of your recent appointment as sales and marketing manager of Zünd UK, how do you intend to boost UK operations, drive and support sales of the Zünd range and explore other markets?

One of the key requirements for me is to further establish us in rapidly growing markets, such as the composite sector, and to diversify and find new markets where we can supply our equipment. By becoming less reliant on our traditional industries, we will be able to expand whilst also continuing to deliver our mission of being the market-leading cutting table supplier in every market we enter.

Q) What are the types of demands placed on your company by today’s customers?

Much of the time, there is a real desire from both sides to build a partnership between us as a supplier and our customer. This works on many levels, and increasingly we’re utilising our flexible approach to work with third-party companies with the aim of providing a tailored solution, which allows us and our chosen partners to really stand out. The support aspect is another key point, as this continues the working relationship and it’s really important for our customers to know that we are available for any kind of query they may have.

Q) What is driving flatbed cutting machine technology and why and what are today's customers looking for in terms of performance solutions?

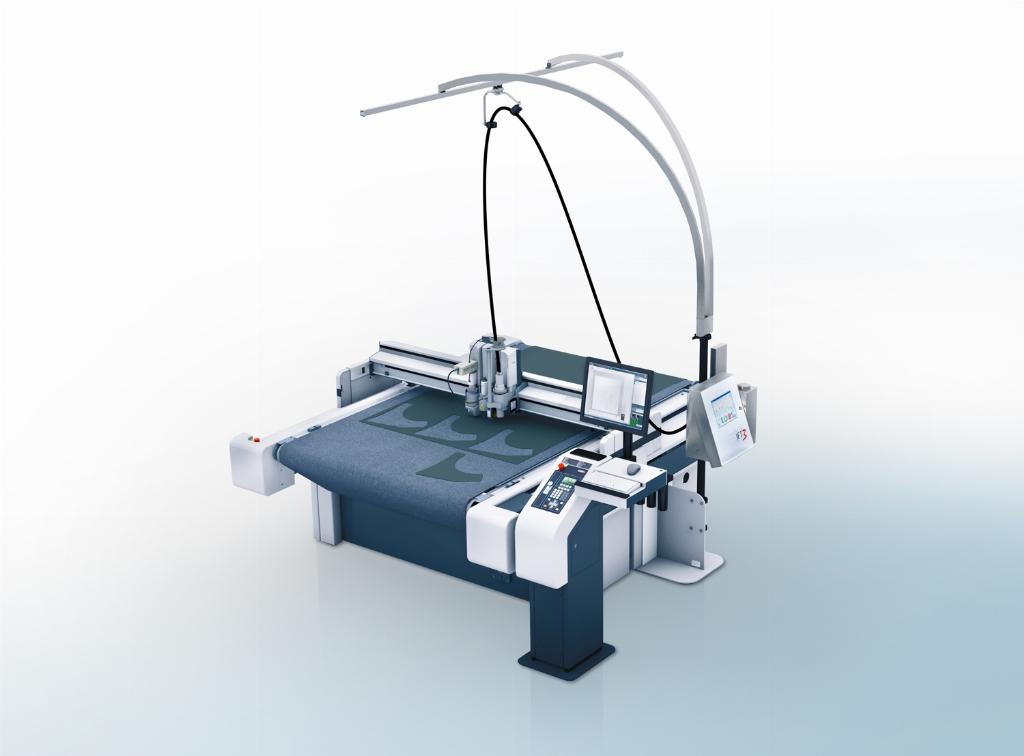

For a number of years now, the trends have been pointing towards making the machines more productive to keep up with the rate at which software developments are being made. Therefore, developments to the Zünd range in recent years include the dual-beam D3 digital cutter, inkjet printing systems and projection systems to help speed up the loading and picking of cut components. Our customers are also increasingly looking for ways for the software to be integrated to existing software systems. If catered for, this makes the integration of a new cutting machine far easier, and our bespoke-to-Zünd software Zünd Cut Centre is very open to many different systems and files which enables us to provide an easily-integrated system, and which is both easy to use and highly productive for the end-user.

Q) Tell me about the kinds of composite-related materials your machines cut, the material nesting software employed and the levels of after-sales support and machine training provision offered to customers?

The most common composite materials we can cut are prepreg carbon fibre, dry fabrics, Kevlar, honeycomb core products and various types of foams. The G3 and D3 series machines can cut up to a thickness of 50mm on certain materials, such as foams.

We utilise our own Zünd Cut Centre software for driving the machine and it can also be used for nesting either at the machine or remotely. As it’s all one software package, the integration between the nesting side of it and the CAM elements are seamless. Added to this is the extensive functionality from the package, which includes a queue system for job scheduling and productivity reporting.

Many of our machines are used in 24/7 production environments, but most of the time are attended to by an operator to pick cut parts off the machine or picking area, and for loading new material onto the rear of the machine. Options are available to fit robotic arms and sheet feeding systems to automate certain aspects, but most of the time an operator is involved or nearby in practice.

At Zünd UK, we take care of the training and support with a dedicated team of service and technical personnel. We also offer various levels of maintenance contracts, and even the possibility of tailoring these to suit the end-user.

Q) What differentiates your company from the competition and why should a customer use you over your nearest rival?

Our machines are unique in how they can be configured to the exact needs of the end-user. By choosing between a range of widths, lengths, material handling options - plus a huge variety of interchangeable modules and tools - it ensures that the end-user ends up with a machine that’s tailored to their needs. The robust nature of the machines is also a key factor – they are built to last and we have many machines still in the field that are well over 20 years old, still running in production environments. They are built to the highest standards and each machine is built in Switzerland to order. Finally, the flexibility of configuring a machine ensures that upgrading it at a later date is very easy, so the machine can adapt and expand its capabilities based on the needs of the end-user’s business. These factors combined ensure our confidence in providing the highest quality machines for the most demanding of requirements.

Q) How do you see the future of the UK’s composites manufacturing industry and particularly subcontract kit cutting evolving in the future?

From conversations with our customers the overall trend is one of too much work for the number of suppliers who can carry out that work. So, we are expecting to see subcontract kit cutting become a genuine subsector within the UK composite manufacturing industry, with new companies and divisions within established companies being set up to cater specifically for this business. The future looks bright for the UK composite industry and we’re excited and proud to be a part of it.

Q) Where do you see the biggest business challenge coming from next year?

The potential unknowns around Brexit are certainly posing a challenge, but we will know more on that one very soon! The other challenges come from bespoke, large-scale projects where we aren’t just supplying a cutting machine – it’s a complete workflow solution that’s required. As the requirements change between each company, we can’t have a ‘standard’ solution, so we will take each challenge as it comes to us. But these projects are challenging for the right reasons and will allow us to expand and continue to develop our knowledge and systems - we are excited to see what the future has to offer!