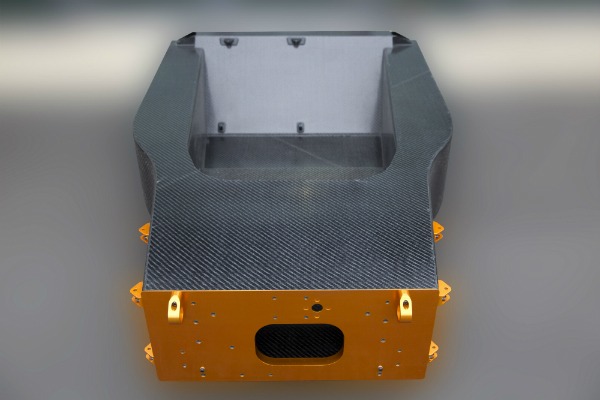

Unique lightweight chassis structure ‘ToPCat’ for new EV project

Swedish electric car company, Uniti has named KW Special Projects (KWSP) as the official engineering partner for its new affordable electric vehicle (EV) programme, Uniti One.

The agreement will see KWSP’s unique carbon composite vehicle platform exploited for the vehicle build, chosen for its lightweighting, thermal management, and structural advantages.

Named ToPCat, KWSP’s carbon composite chassis vehicle platform can be developed for a fraction of the cost of traditional methods. It offers an alternative to more conventional CFRP thermosets, traditionally seen in motorsport programmes. However, while CFRP can be expensive to process, labour intensive and not easily recyclable, ToPCat is fully recyclable and has been proven to shorten engineering cycle times by 83%. Independent tests have also demonstrated financial savings in both tooling costs and unit costs when ToPCat has been used as an alternative to other methods.

Kieron Salter, managing director at KWSP, commented: “Uniti One is a really exciting project which will demonstrate the lightweight and structural advantages of ToPCat when compared with alternative methods of chassis design and manufacture. Made possible by co-funding from the UK’s innovation agency, Innovate UK, ToPCat was key to attracting Uniti to the UK, where the company hopes to take advantage of Britain’s expertise in materials development and lightweighting.”

ToPCat was promoted by KWSP at the recent Advanced Engineering 2018 show at Birmingham NEC.