The advantages of building true partnerships

In a Q&A session, Roth Composite Machinery’s managing director, Dr Andreas Reimann explains how the company has grown to become an expert in the field of special filament winding machinery construction.

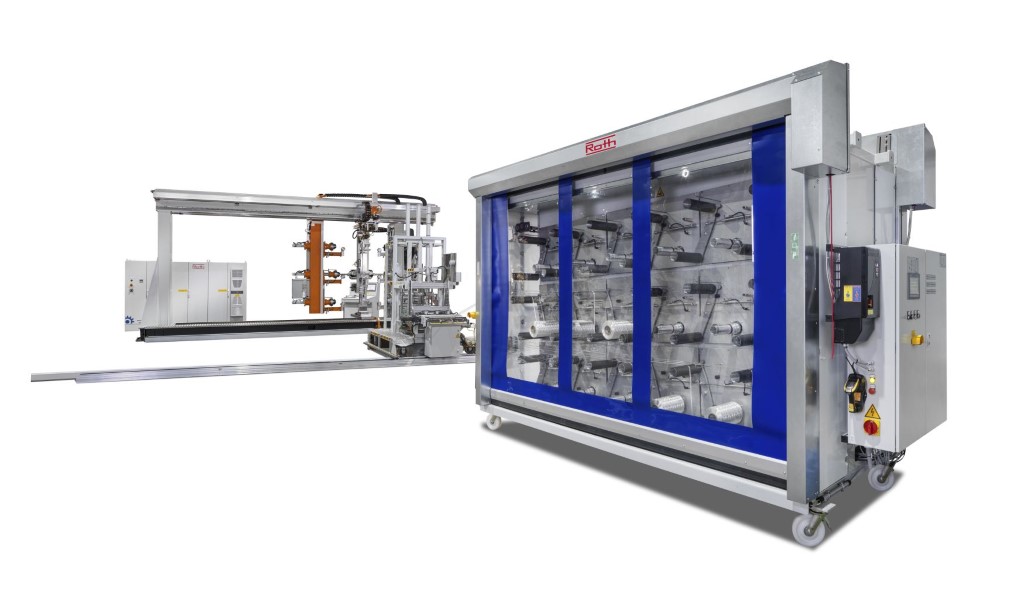

Roth Composite Machinery builds filament winding machines suitable for the manufacture of lightweight products made of high quality plastic materials that use exceptionally durable fibre reinforcements.

In particular, these are used in the aerospace, automotive, sports industries and power generation. Synthetic resins and thermoplastic materials are processed on these machines and systems using reinforcing fibres, usually made from glass or carbon fibre.

With over 500 filament winding machines in use around the world, Roth Composite Machinery says it can look back on almost 60 years of experience in the development of filament winding machines. Such equipment manufactures filament winding products of up to 125 tons in weight and 30m component length are worldwide trusted upon in serial operation. The portfolio comprises winding machines with up to twelve CNC axes.

With regard to fully-automated production lines, the company has almost three decades of experience, including pressure tanks for water, LPG, CNG and hydrogen and parts for the Ariane space rocket and aerospace industries.

After the delivery of machines for winding the rocket boosters of Vega, Ariane 5 and 6, other aerospace companies are relying on Roth equipment and have placed orders for seven machines in total within the last one and a half years serving applications like rocket motor cases, housings, tanks and satellite rods.

Roth Composite Machinery will also be participating in the Mission Hydrogen Online Conference on October 8, 2021 and at a webinar on the Mission Hydrogen platform on September 29, 2021 and will speak about its FWA 1 - Duplex machine.

Q) What are the types of performance demands placed on your company by today’s customers?

Customers require innovative machine concepts that are tailormade to their production requirements. Roth Composite Machinery is known in the market as a reliable partner who supplies high quality production lines that meet the performance demands regarding full automation, increasing processes’ productivity, low maintenance, longevity and durability.

The technology involved also requires a high level of customer service including consultation, planning, advice in machine operation and for example the kinds of filaments that are needed to achieve the requested product properties and the respective quality. As a machine builder, we are used to being very flexible on customer requirements.

Q) Typically, what are the kinds of products you are asked to produce for your customers?

In addition to the aerospace industry, the automotive industry and industries involved in new sustainable mobility concepts are increasingly benefiting from our products. Among them are manufacturers of high-pressure tanks for compressed hydrogen or natural gas or liquefied petroleum gas vessels, for example.

Q) With increasing demands for faster production rates, plus the reduction of the manual layup processes, how much consideration are you giving to the implementation and use of automation?

Serial production – especially in automotive sector - requires a high level of process repeatability and production accuracy. This can be done only with high quality standard machinery and high levels of automation.

Q) What are the main focus areas of your current R&D efforts? Are there any particular ongoing research programmes you can talk about?

With regard the developments of future mobility concepts, one of our focus areas is the development of machines for the mass production of hydrogen tanks using the filament winding process. We also perform a lot of R&D concerning improvements in productivity, performance and automation. To drive research forward, we are a partner of scientific working groups in universities and participate in other industry partnerships.

Q) What do you feel are the most important assets of a company?

A combination of these points leads to a successful package to be competitive in today’s demanding market structures. In our view, the company’s people are an essential asset. Long-term experience and motivation and cooperation within teams and the ability to cope with frequent changes in customers’ demands and specifications - especially within the execution of customers’ orders - is the basis for running a business in such a strong customer-oriented way. We are convinced that our key to success is an absolute focus on the client. This is also part of Roth’s company principles.

Q) Are you concerned that competing technologies like additive manufacturing may surpass filament winding?

Filament winding is a classic additive manufacturing process. We see 3D printing as complementary, rather than a competing process to the filament winding. The technologies interact with each other and can build on each other, depending on the application and as a result, contribute to a successful product.

Q) What particular aspect has helped your company get through the pandemic? For example your agility, knowledge and experience gained over the last few years?

These are all values that we can assign to ourselves. This year, we are experiencing a high demand from the industries previously mentioned for machines for the manufacture of lightweight structures using the filament winding process. Therefore, we have been able to adapt our work systems and increase capacities. The demand for high-performance machines is increasing, and we are meeting this demand with our new high-performance Duplex machine. Its strong frame design keeps the dynamic of the accelerated production process with an increased quantity of laid fibres under control with ease. Our new Filament Winding plant is available with three, four or five spindles. It is suitable for production processes for wet, dry or Towpreg winding procedures by using all common types of fibres, especially carbon and glass fibres.

Q) Finally, would you say that your long-standing partnerships have brought huge benefits, particularly as trusted relationships can lead to a better way forward for all?

A successfully completed project is the basis for a long-term customer partnership as it creates trust in future projects. Our motto as a true partner is to uphold the idea of service - even after the order has been completed - thus revealing competitive advantages. For example, we support our customers in setting up machines and train them in their operation.

Customers benefit from our experience and our employees’ know-how. The resulting customer relationship is valuable for the further direction of the business. We have a similar situation on the supplier side. Our supply partners are currently going through the ups and downs of market development with us - this only works within the framework of trusting partnerships.