Sanded to perfection

Mike Richardson discovers how Suhner harnesses its automation technology to save time, improve repeatability and remove the grind from manual and repetitive carbon fibre-reinforced plastic (CFRP) surface finishing processes.

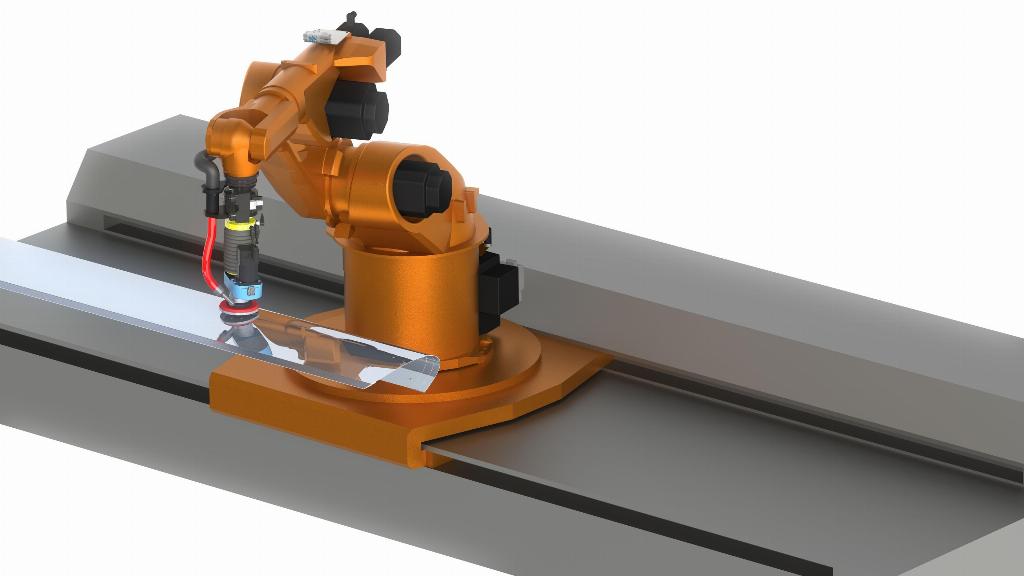

Abrasive experts, Suhner Automation applies its experience in the field of process automation to develop a new robotic technology for the purposes of surface machining to perform comprehensive tasks for CFRP aerospace components.

Whilst composite materials are widely used throughout an aircraft assembly, they are sensitive to the quantity of material removed, as well as potential impact damage. In addition, some parts contain an integrated copper or aluminium mesh to provide lightning strike protection. To maintain part integrity, it cannot be sanded, but by automating the process, Suhner says it can offer full control over material removal with its ROBOTsander.

Developed for aircraft assemblies, such as control surfaces, fuselage segments, leading edges, engine inlets and engine components, the company says its ROBOTsander sets new standards for automated surface machining. As an adaptive and capable surface treatment solution designed to offer significant reduction of cycle time and usage of abrasive material, the ROBOTsander meets surface treatment needs and requirements in a cost-effective manner within minimum deployment time.

Suhner can offer an intensive programme to optimise the customers’ process, i.e. sanding paper, path, speed, to reach the required quality in a minimal duration. In addition, a solution has been developed to automatically exchange the sanding discs of the ROBOTsander’s end-effector. The newly developed and Suhner patented ESW150 Abrasive Changer system enables the renewal of sanding discs in less than 10s, which is said to outperform any other available system on the market. The ESW150 offers a fast abrasive change time and reduces non-productive time to an absolute minimum during the sanding process.

Get beneath the surface

By the time the part has reached the surface treatment stage, it usually means that it is at the end of the production process. This means that the part includes all its added value and is close to final delivery. A process failure, part damage or delay impacts the manufacturer’s margin on their parts and its on-time delivery performance as subcontractor. Therefore, it is critical to ensure process stability, for proper prediction and reliability.

The benefits include a fully-controllable and stable process; a fail-safe controller set up to safeguard high-value parts as well as operators; fewer consumables which means less waste and an optimal use of resources; stable, repeatable working process safeguarding the high-value parts; minimal deployment time for new applications and overall cycle time reductions from digital process simulation.

Meanwhile, Suhner has installed a new robot R&D cell in its Lupfig, Switzerland facility to further develop the ROBOTsander system to include 3D surface scanning and parts recognition, optimise process development to further reduce cycle time, improve process steps, and process parameters definition (speed, force, paper type) for new customers.

During process developments, Suhner uses its expertise to evaluate the best abrasive materials, corresponding resistance and efficiency to define the correct process parameters and save process time. Developments in offline programming are said to make it possible to run robots in a virtual process, i.e. a digital factory, before committing it to the actual shopfloor to help reduce pre-production niggles. Thanks to Suhner’s approach, each process, as well as the complete robot cell functionality can be properly analysed. This allows optimisation, performed well in advance, to the initial delivery, further reducing process risks and overall deployment time.

In close collaboration with digital factory software partner CENIT, Suhner has developed a specific label surface treatment technology packet dedicated to the ROBOTsander. Based on the CAD surface model, working parameters can be determined, digitally tested and with the use of an interpreter directly downloaded into the robot controller. Follow-on verification and validation of critical qualification, parameters can either be performed at the Suhner Robot Test Cell in Switzerland, or at any customer location worldwide.

In addition, Suhner can evaluate the proper robot and cell dimensions, thus confirming reach on the complete part, checking and correcting potential collisions or forbidden moves of the robot at the very beginning of the study.

New factories get smart

Thomas Combemale, (above, top) head of the aerospace team says the company is already onboard with the Smart Factory solution, and thanks to its extensive use of offline programming (OLP) is at the stage where this philosophy can be fully implemented. Based on Industry 4.0 objectives and the usage of the Suhner Digital Factory Monitoring System, the customer can monitor – onsite or remotely – the ROBOTsander’s performance, including online data recording, process diagnostic and optimisation, predictive maintenance and remote product support, as well as spare parts and usable management.

Recent statistics claim skills shortages and the need to recruit young talent and demonstrate what an exciting, diverse and rewarding career engineering can offer young people entering the industry. But, just how many jobs will be available when the increase in automated manufacturing processes will clearly reduce the amount of human involvement? What new jobs can be created?

Combemale says, the industry is suffering from a manpower shortage for surface finishing. It can be physically exhausting and repetitive, and because of the dust, unhealthy too. Many companies are having difficulties finding people with the correct competences for this type of work, so automation is solving this issue. Also, some of Suhner’s customers have commented that the younger generation “only wants to play with computers” and doesn’t want to integrate with dirty jobs, so this is what its robot cell proposes: simply a bigger and much more efficient tool.

Such a cell requires an automation engineer to maintain the robot, i.e. maintenance, possible new programming, plus a manual operator with process knowledge to perform local repairs, corrections or any specific jobs that do not fall into the robot’s scope is also required. Ultimately, such a robot system does not only provide cycle time and cost reduction values, but also a new work environment for skilled and talented workers.

In summary, robotic automation technology and abrasive expert knowledge, as combined in Suhner’s ROBOTsander, offers the benefits of removing manual labour from hazardous operations, improved consistency, process repeatability and quality, obviating human issues like sickness, lunch breaks and variable skills levels, and coping with production fluctuations. Meanwhile, Suhner continues the development of its automatic system to change sanding paper and ongoing research into the integration of optical technology for part calibration and tool calibration.