Seal the deal

Designed to offer a perfectly sealed edge finish when processing dry fibre materials, Zund says its innovative new Heat Sealing Module (HSM) is all set to become hot property in the composites sector.

Zund’s new Heat Sealing Module (HSM) has been specifically developed to process dry fibre materials. The HSM (patent pending) prevents the material edge fraying by sealing the loose fabric edge on the cutting bed. This avoids loose fibres, cross-contamination, and part distortion when handling.

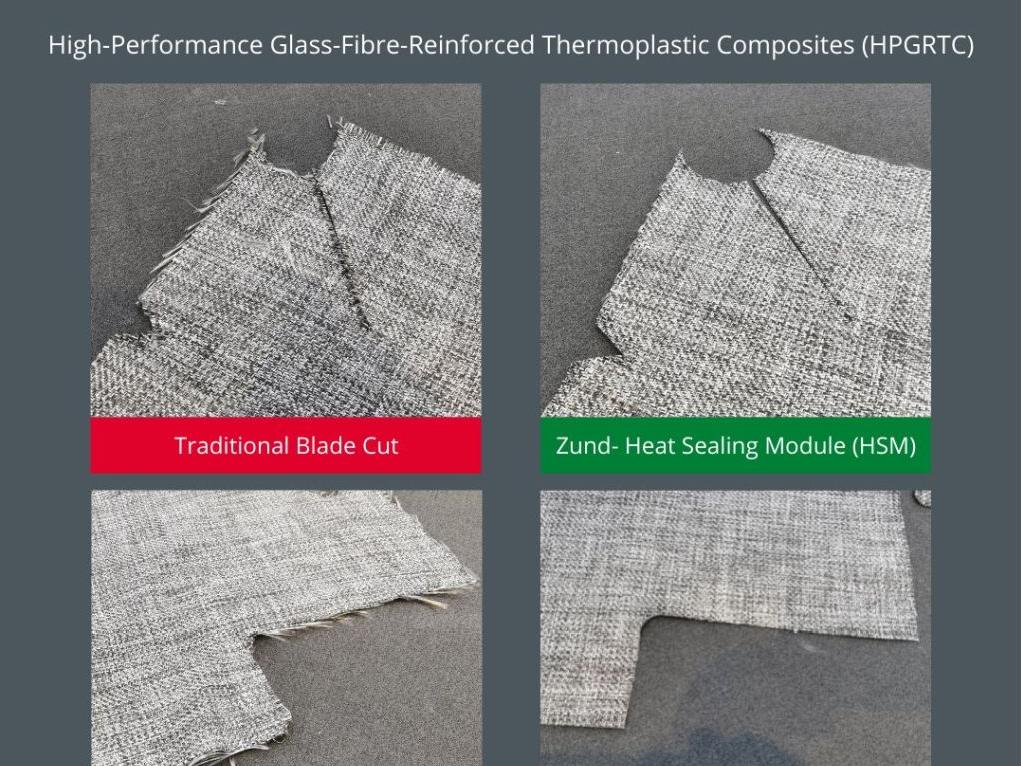

With the HSM, customers in the composite industry processing high- performance glass-fibre reinforced thermoplastic composite (HPGRTC) can now move their manufacturing to the next level. Traditionally, when processing HPGRTC materials, the loose fibres are free to move and fray, producing weak and irregular edges. This can also cause significant contamination in the production cutting environment.

The HSM works by sealing the edge along the cut path prior to cutting. This operation can be performed at high speed in any direction and is not limited by the profile shape or complexity. The various benefits associated with the HSM will greatly improve production efficiency.

Perfectly sealed edge

The HSM offers a perfect sealed edge finish and both the cutting and subsequent processes benefit from ease of handling parts and a clean and cross-contamination-free environment.

When mounted on a Zund digital flatbed cutter, the HSM uses hot air to heat seal the perimeter of a part prior to cutting. Driven by a fully digitally controlled process, the Zund software commands the module over the composite material, sealing the fibres around the part edge. In next step, Zund’s high-performance Power Rotary Tool (PRT) cuts the material in full, without leaving uncut or loose fibres behind. This enables fully unattended automation at the cutter end. Once the seal and cut operations have been completed, the processed parts benefit from complete stability and ease of handling, and comparable handling as with prepreg composites.

Zund says it has technically solved a long-standing customer problem with an innovative idea and converted it into a mature technical solution that fulfils strict requirements in terms of quality, safety and compliance.

In terms of the value created by the use of composite materials, the HSM, facilitates drastically improved clean cutting and handling of dry fibre material processing with thermoplastic material content, therefore overcoming major, industry wide challenges and enabling its widespread use.

“At Zund, when a customer approaches us with a technical challenge, we collaborate both with the customer and technological solution suppliers to develop a solution,” stated a Zund spokesperson. “In the HSM development, the industry need was there, and we took up the challenge to offer a complete solution. Throughout this detailed R&D project, many iterations were developed in-house at Zund UK and in close collaboration with the end customer. After many months of development and consultation, we have now arrived at the production-ready HSM that is ready to completely revolutionise the thermoplastic reinforced materials industry.”

Maximising market potential

The HSM fits seamlessly into the modular tool positions on the Zund cutter and can be used in a variety of applications, including on existing Zund machine installations. Combined with its key benefits of streamlining the cutting and kitting process, the innovation is providing maximum benefit to Zund customers worldwide not only in composites, but also in textiles and technical textiles applications.

In summary, Zund’s HSM contributes to the common good with the key function of enabling fully-automatic fabric cutting and ply kitting in the manufacturing process of lightweight components for electric/fuel-cell mobility. Ultimately, the overriding goal is to minimise CO2 emissions in line with the global decarbonisation strategy. According to Zund, an industry-wide issue now no longer exists through the creation of this innovative tool – there is no other comparable solution available globally.

For more information and live demonstration of the Heat Sealing Module, visit the Zund stand (V110) at Advanced Engineering UK 2022.