Saertex expands product range with pultruded planks for rotor blades

To enhance its range of fibre-based materials for composites in the wind industry, Saertex will introduce a new product line at JEC World 2022 in Paris.

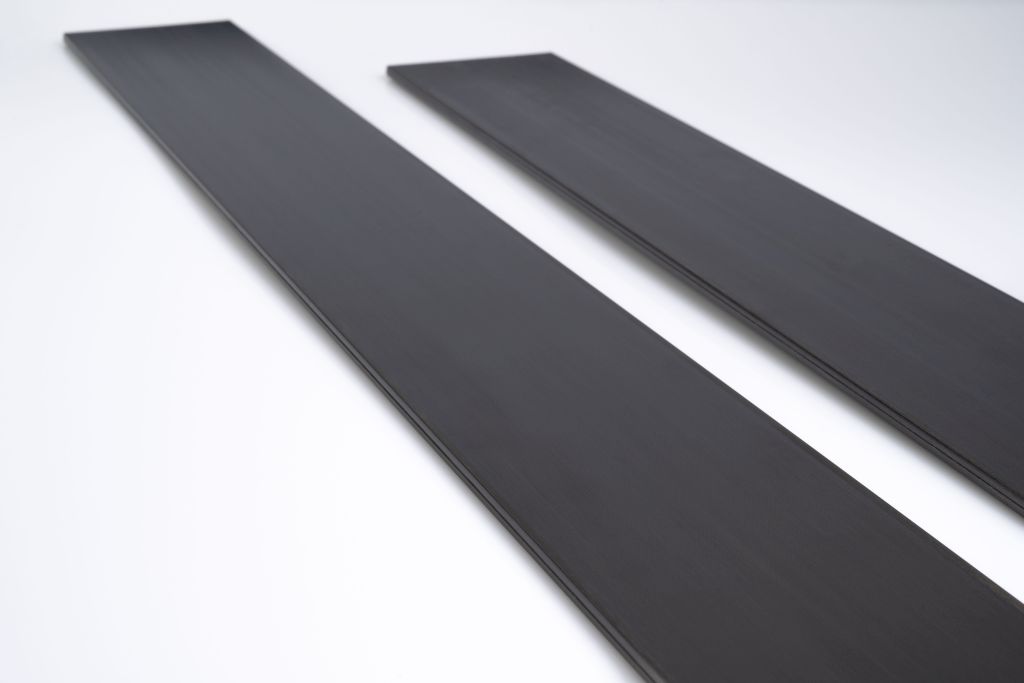

The new pultruded profiles product line SAERplanks will complement the company's offering of non-crimp fabrics made of glass and carbon fibres for the spar cap section within rotor blades. At JEC World, Saertex will add an offer of pultruded planks out of carbon fibres to its existing product range of reinforcement materials.

“The market launch of our pultruded profiles SAERplanks will open up completely new opportunities for us to reinforce the innovation activities of our customers in the wind industry,” said Christoph Geyer, CEO at Saertex. "This enables us even more to deliver the most efficient materials – across technologies – adapted to the requirements of our customers."

The company has been actively working in recent years to develop an innovative in-house manufacturing capability for making pultruded profiles with elevated strength and stiffness. The first production line is about to start in Saertex headquarters in Saerbeck, Germany. The SAERplanks are based on heavy tow carbon fibres produced in a newly developed pultrusion process, no longer based on a traditional resin bath.

“There are two outstanding things about SAERplanks. On the one hand, we combine the carbon fibre with a new hybrid resin system, developed in collaboration with AOC resins,” stated says Hans Plug, manager pultrusion at Saertex. “And on the other hand, we established an innovative manufacturing process for higher productivity based on a closed resin injection system. For our customers, this new technology offers a more sustainable production method, in combination with a more consistent quality compared to products currently available on the market."

Saertex has been partnering with AOC Resins in this project to achieve the high requirements for reliable performance, high productivity, and minimum scrap rates. AOC managed to develop a high-performance hybrid resin specifically for Saertex. Through multiple product development iterations and thorough experimental design, experts from Saertex and AOC have been able to optimize resin composition and key process settings. As a result, Saertex is now able to run its process consistently, with excellent quality and performance reliability.

“AOC really likes to work with customers in a close collaboration mode to develop unique resin solutions for their processes and specific application requirements, supplying products around the world,” explained Fons Harbers, marketing & sales vice-president for AOC EMEA. “I am very proud that AOC has been able to support Saertex here and managed to make their process development a true success.”

The multiaxial fabrics manufactured by Saertex have been used to produce rotor blades for over 30 years. While non-crimp fabrics made of glass fibres were initially used, Saertex materials made of carbon fibres are being used more and more as rotors become longer. The development of unidirectional and multiaxial fabrics for the wind power industry will be continued and intensified at Saertex in addition to the new range of pultruded products. For example, the company has already recently introduced Easy Drape UDs, a product innovation in the fiberglass sector, and will also introduce a new carbon UD for spar cap applications at JEC World.

"One-stop shopping is an important component of our offering for a resource-saving future. It allows us to support our customers to reduce complexity and optimise efficiency," concluded Geyer. "Our global footprint with locations on five continents plays an important role in this - especially when it comes to supply chain reliability and sustainability aspects. We are therefore planning to invest in additional production capacities worldwide for the new SAERplanks. This will be proceeded in line with our customers’ needs."