Big names, big gains

Mike Richardson hears from advanced composite solutions specialists, Retrac Productions’ managing director, Andy Carter about the company’s purchase and its use of CMS CNC machine tool equipment.

There’s no point in doing anything by halves, is there? When Retrac Productions decided to enhance it’s 5-axis pattern shop capacity it approached Italian CNC machining centre specialist, CMS. Big names mean big gains for CMS’ customers, and with a company product range that reads like a ‘who’s who’ of Greek mythological gods, CMS - established in 1969 to provide 3- and 5-axis CNC equipment for a wide variety of markets - ascended its metaphorical Mount Olympus to give Retrac exactly what it needed.

Founded in 1972 by John Carter, family-owned Retrac has expanded over the years to encompass Retrac Productions and in 1998, Retrac Composites. It has also continued to maintain its ethos of quality and customer support, whilst investing in equipment and a growing workforce.

A background in supporting the aerospace, automotive and motorsport sectors has enabled it to embed its engineering experience into the growing composites side of the business, giving the group an unparalleled capability to support its customers’ demands across a huge range of projects. So, is there a good synergy between different sectors?

“There is synergy between the different industries in the projects we cover because the advanced materials and manufacturing techniques we use create a huge crossover,” begins Retrac Productions’ managing director, Andy Carter. “Our engineering background means we’re in a position to flex with any motorsport demands, but adding an engineering viewpoint within the composite sector.

“Our knowledge and experience cover a wide range of products and materials – from simple machined to complex multi-axis components in different materials, jigs & fixturing and mould tools – all of which crossover into composites. We’re manufacturing mould tools from patterns that we produce and then components from those mould tools, each of which would need machining and assembly with further machined metallic or plastic bonded components as well.”

Never a dull moment

In terms of the kinds of customer demands Retrac faces, Carter says Motorsport is becoming much more focused on accuracy of composite components that are being used across a wider variety of parts. They are being held to much finer tolerances – moving away from hand trimming to more accurate and repeatable 5-axis CNC machining improving component performance.

“Our motorsport customers need to know that when they assemble the next part onto the car trackside, it’s going to work seamlessly. To back this up, our quality department is able to verify those components and mould tools are correct before they are delivered. This indicates how motorsport demands are progressing toward those similar to aerospace.”

Naturally, Carter is aware of the demands of price, quality and delivery – they are a given, but just as important to Retrac’s new and longstanding customers is the company’s in-process and after-sales support.

“We are often relied upon to help find solutions to design issues during the manufacturing process, foresee problems before they arise and then react swiftly for the customer so that no time is lost and delivery dates don’t suffer. The motorsport and aerospace sectors both demand quality, accuracy and producing a part it can rely on to be 100% correct. We have to be able to support their quality requirements with our in-house facility to ensure everything is correct to the drawing and CAD model, is traceable and all the materials are answerable to. There is more emphasis on the background work rather than just on the machining of the part, and whether it’s a one-off pattern or tool or multiple components, they need to follow the same high standards.

I ask Carter whether he is seeing any spikes in production demands, i.e. the forecast ramp rates predicted by aerospace OEMs or for more composite cars from the automotive industry to satisfy lightweighting requirements.

“Increasingly more projects are focused on the benefits of advanced materials to provide lightweight components with enhanced performance and the need to productionise these advantages through our tooling. It’s all very well being able to produce a lightweight carbon fibre component, but how are you going to productionise it and ensure that every one you make is exactly the same. The mixture of our engineering background and composites knowledge go hand in hand with what our customers see as their future projects. We can only see an increase in demand for the kinds of knowledge and capacity we are able to offer.”

Enter the Cronus

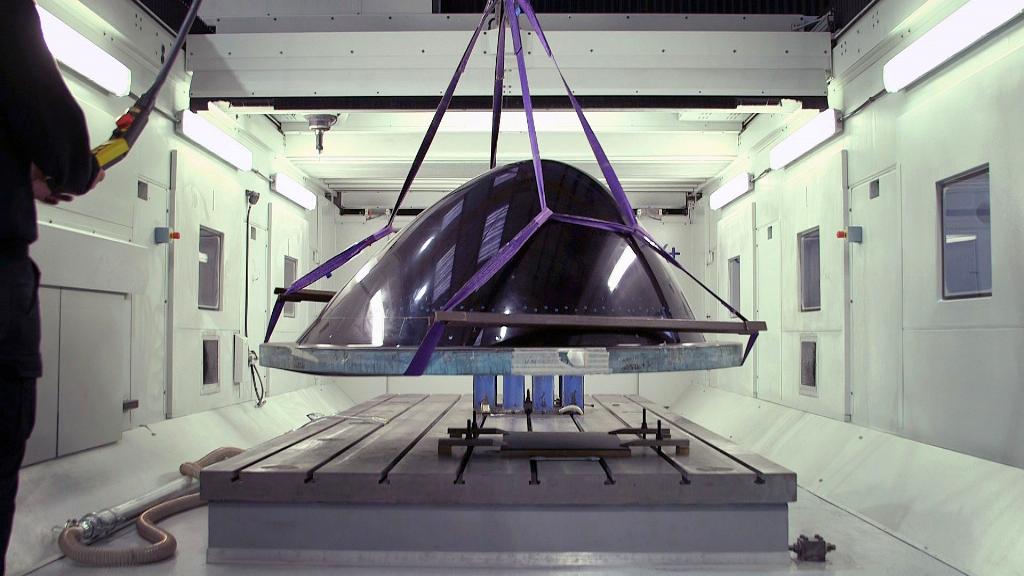

Retrac purchased a CMS Cronus CNC gantry milling machine around five years ago to support its growing composites work and the expansion of its own patternmaking in Retrac Productions’ facility. The Cronus delivers elevated levels of accuracy and repeatability, whilst the 32kW spindle delivers high levels of torque at lower RPM. Carter notes that CMS is very responsive on the maintenance and service side of the machine and if there are any issues, they are very contactable and reactive.

“We had to make a decision about the purchase of a large machine to support some of the projects our composites facility was being asked to do. We wanted a machine tool that had a robustness and accuracy for both our composites and large-scale aerospace work in terms of jigs & fixtures, patterns and tooling. Our focus was to have an affordable large machine of a size that would support our 6m autoclaves. Looking into the machines available, CMS proved to have the perfect fit.

“More recently we’ve also selected the smaller capacity CMS Antares. For us, the Antares was our ‘go-to’ machine because of its price/performance ratio and the already mentioned, service levels available from the UK support centre. Given that we were looking to use the Antares for smaller patterns and composite components, it made sense and it was a very easy choice to make in the end.”

CMS UK’s division sales and marketing manager, Graeme Cartwright adds: “Given the reputation of Retrac within the composite sector, we were delighted when they chose to install the Cronus machine. It was also particularly pleasing when they chose the Antares as their second machine - not only for its performance capability - but more importantly because of the levels of service and support available from our UK office. It’s a pleasure to work with such a professional and progressive company.”

According to Carter, being a family-owned, privately-funded business means Retrac has to be very shrewd with its capital equipment purchases, whilst keeping abreast of the latest machine tool developments, making wise investment decisions in order to maintain his father John’s quality philosophy.

“It’s important that we are able to support our customers’ requirements for accuracy, speed and quality with the right machines,” he concludes. “CMS falls into this bracket for us. Retrac has a very good reputation for quality and delivery and this has to be maintained.”