Doing things differently

With a host of composite solutions to fit your technical, manufacturing, lead-time and budget requirements, Mike Richardson hears how PRF Composite Materials’ recent equipment and facility expansion project ensures the company continues on an upward trajectory.

PRF Composite Materials is a leading manufacturer and supplier of high-performance materials for the composites industry. Since its formation in 1982, PRF has established a reputation for high quality service, supplying the automotive, motorsport, aerospace, defence, wind energy, marine, sports and medical industries.

In Summer 2018, PRF opened its third site, a purpose-built facility which now houses its growing sales and sales admin teams and increased warehousing and cold storage facilities.

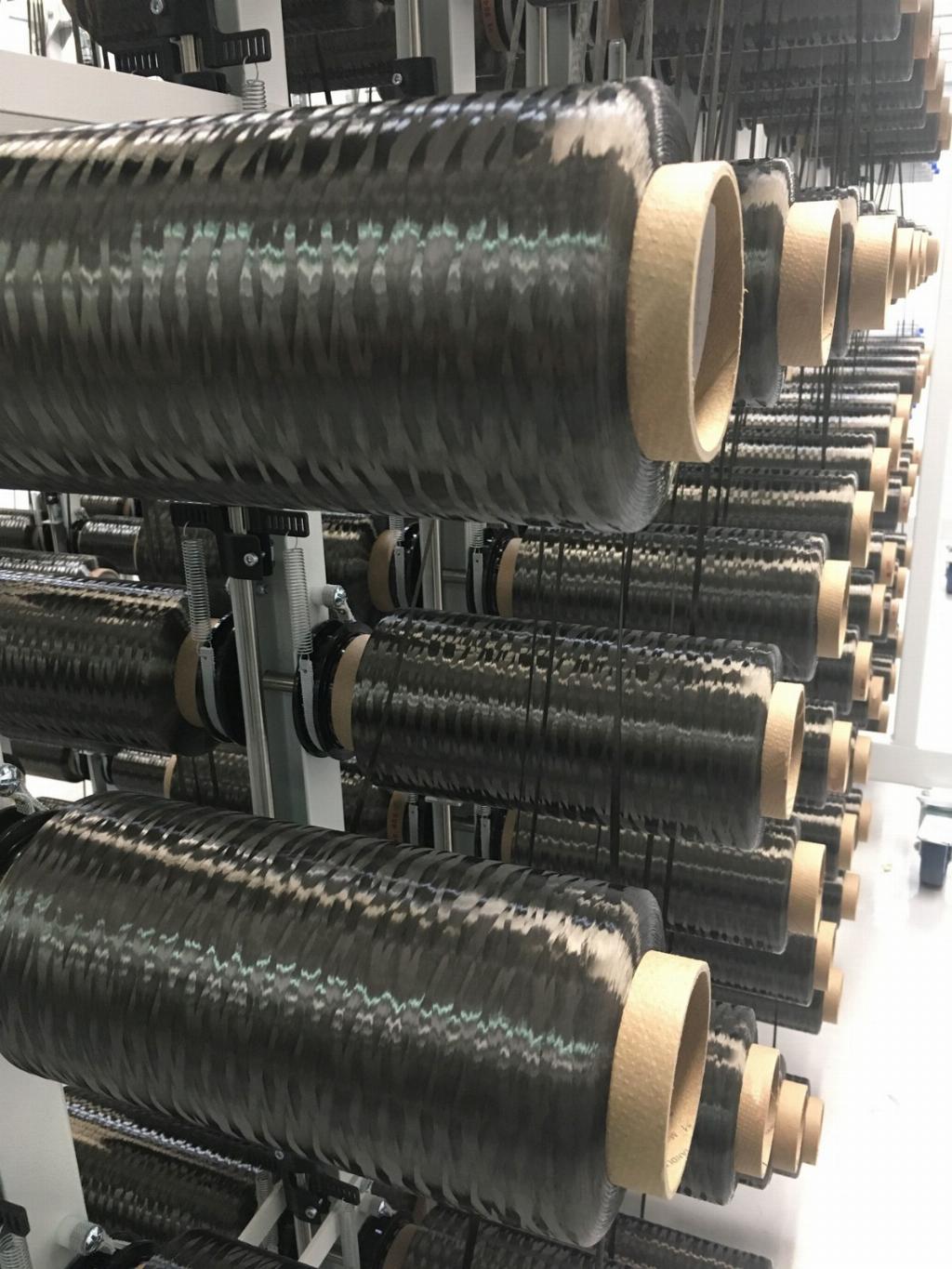

“We have been at this site for a year now and it has enabled us to extend our head office, increase our manufacturing capabilities and install our new state-of-the-art unidirectional line,” begins company sales & marketing director, Hannah Khusainova. “We are also extending our lab facilities to support our product development team and provide further technical support for customers.”

The new unidirectional prepreg capability includes carbon materials from 80 to 600gsm at standard widths of 300mm and 600mm.

“We are receiving fantastic feedback on our new UD prepreg materials and our new prepreg system, RP542-4 which is available on broad loom fabrics and UD. Our UD line allows us to really complete our prepreg offering, providing a full and comprehensive range of materials for our customers.

“In the process of these changes, we’ve also undergone a rebrand, which retains the feeling of our core identity, but also brings our brand up-to-date with who we are now, showing our evolution into a leading manufacturer of innovative prepreg materials. With our new line, we will continue to push boundaries and focus on innovative product development that enables our customers to get better results, faster and in a more cost-effective manner.

The chief reason for this expansion comes down to growth and demand. Khusainova says that PRF always intended to commission a new UD line.

“However, we’ve been careful with the schedule of our expansion and growth in order to consolidate new products, manufacturing lines and to grow our team before moving onto the next phase. The UD line gives us the opportunity to offer a full range of materials and provide customers with the high quality PRF prepreg they require in our UD version, supported by shorter lead-times and innovative, in-house resin system development. In order to create space for the new prepreg line, we commissioned the building of a third facility to also accommodate our growing sales and sales admin team and a larger warehousing facility.

“In the last seven years, we have invested around £4.5 million in the expansion of the company, R&D and commissioning manufacturing equipment. We will continue to invest in supporting the company’s expansion and are particularly passionate about quality of raw materials, state-of-the-art machinery, manufacturing efficiency and innovative R&D.”

To adapt a quote from Brian Clough: ‘PRF wouldn’t say it is the best prepreg material supplier, but it is in the top one’. Would you say that now with this expansion, PRF is now the top prepreg supplier in the UK?

“It depends on how you define ‘top’ - we’re not the biggest, but with the quality of our prepreg, we believe that we are market leaders,” states PRF’s managing director, Robert Burnell. “We are particularly good at fibre and fabric control and have been chosen by top marque companies requiring visual quality materials. Besides being particularly good at fibre alignment and fabric control, our chemists are formulating new systems - which not only perform particularly well with regard to mechanical properties, but also the feedback from the shopfloor is that the material handling is superb. We’ve also concentrated on improving the out-life of our systems, particularly our low temperature tooling products.”

Adept at adaptation

With strong competition in the UK market from long-established prepreg manufacturers, PRF approaches prepreg from a different perspective. Its range is something that it has developed from scratch, working through customer requirements and how it can improve on what is traditionally offered in the market.

“The challenge is always trying to improve on the current offering in the market,” Burnell continues. “Being a relatively new prepregger in establishing our manufacturing over the last 10 years or so, we’re not going to make good business by copying what’s already out there. We need to improve on the current materials in the market, most of which have been originally developed 30-plus years ago.”

In terms of typical examples where PRF’s prepreg material products have particularly shone above and beyond those of similar competitor offerings, Burnell believes there are particular products where his company is highly-competitive, if not market-leading.

“Our range of tooling systems - particularly our RP802 overnight cure - and the length of out-life these products offer, provide customers the opportunity to choose the system that best suits their requirements,” he states. “The longer cure times of these systems allows manufacturers more time to layup the mould, saving hands needed and improving the quality of work. We have received fantastic endorsements for these systems and they are very competitively priced.

“Due to our history, we have an excellent understanding of the various textile technologies, and we bring this to our visual quality prepreg materials, producing superior quality materials that are currently taken by customers working in the high-end automotive and marine sectors. Our RP570 snap cure system is a ‘true snap cure’ system and has a complete processing time of four minutes. It can be removed from the mould tool without cooling. We can achieve an aesthetic finish with the system and believe it to be a ‘class-leading’ product.

“Our levels of service, technical support and the way we work with our customers sets us apart from our competitors. Our lead-times are also highly competitive with our standard materials available within 2-3 weeks from order. And we are continuing our drive for innovation with a growing product development team working hard to improve our current systems further, and to provide further new introductions to the market.”

Make business simple!

Price, delivery and on-time delivery are all givens, but what else do you see as important to serving your customers these days?

“Making business simple – it’s easy to get the impression that some of the large prepreg manufacturers regard themselves solely as engineering companies,” notes Burnell. “Besides being an engineering company, we must not forget that we are also a service company.”

Khusainova adds: “Technical support has always been very important to the way we work with our customers; with our testing lab and in-house knowledge and skillset, we can test our materials to ensure that they meet the customer’s technical and processing requirements.

“Quality and consistency of quality is fundamental and visual quality prepreg, as we’ve said, is an area where we really excel. Also, as an independent SME, we are nimble and responsive to our customers, particularly in terms of short lead times and product development.”

What does PRF feel are the most important assets of a company: a defined strategy, its people, its experience, its use of technology, its location, or a combination of all these points?

“It has to be a combination of all these things,” states Khusainova. “We’ve always concentrated on innovation and quality, and we bring this to our prepreg manufacturing using high quality raw materials, state-of-the-art technology, and innovation in product development.

“However, people are essential; we cannot achieve anything without our team. We are growing at a fast pace and recruitment has become very important for us in this stage of our growth. The right people in the right combination are a very valuable asset. We currently have a large recruitment drive for all parts of our business - from production to sales, admin and management - in order to support our growth.”

Drive and thrive

In Khusainova’s view, what truly differentiates PRF from the competition is a drive for product development and innovation, working with its customers and finding ways to help them solve problems and improve efficiency and cost-effectiveness in manufacturing.

“We have over 35 years’ experience at the forefront of the advanced composites industry and work across a diverse range of industries and applications, which gives us a distinctive perspective,” she ends. “We have a number of product developments to be introduced to the market soon, but the main aspect our team are working on at the moment is fire-retardancy. As always, we will announce new developments on our website and in Composites in Manufacturing magazine!”

Burnell concludes: “As an independently-owned, well-financed family business, our gearing is such that we are able to invest quickly in new plant and machinery. This frees up our decision-making process to respond to the market in terms of product development. We are growing at a pace and if our business continues to grow according to plan, we may be announcing a fourth site in the not too distant future.”