Filament winding finds its feet

In a Q&A session, Composites in Manufacturing hears from Mikrosam’s vice-president, Vele Samak how the company has grown to become a globally-recognised leader in machines and know-how for the composites industry.

In a Q&A session, Composites in Manufacturing hears from Mikrosam’s vice-president, Vele Samak how the company has grown to become a globally-recognised leader in machines and know-how for the composites industry.

Based in Prilep, Macedonia, Mikrosam provides factory automation for modern composites manufacturing and has installed more than 240 composites production lines in over 40 countries. All machines are engineered-to-order using the company’s knowledge from proven solutions in 6-axis filament winding, AFP/ATL robotic and gantry machines, automation, prepreg production and conversion.

Q) What are the types of performance demands placed on your company by today’s customers?

Almost three decades ago, Mikrosam started in the low-end, low-price spectrum. Today, in filament winding, our customers recognise Mikrosam as a high-end and price-competitive contender. This is especially true for the most demanding winding applications. Price, quality and delivery are still as important as ever and we continue to excel here. What we’re also finding is that customers prize flexibility and strong after-sales support. Flexibility comes from the ability to customise the machine with optimisation and automation to achieve higher ROI, or increase quality via inspection systems. Faster cycle times - not just raw machine speed - is a driver now, especially in automotive applications where lower-unit-cost and higher volumes are priority. And customers don't feel like paying premium for that cycle-time again due to ROI.

Q) What are the kinds of products you are asked to produce for your customers?

Our focus is in engineered-to-order machines for winding, layup, prepreg and conversion needs, therefore, all of our products usually have some new technology or capability which drives the interest in Mikrosam. Even low-scale machines, in terms of capacity, contain some of our latest technologies. For example, we delivered a tow-preg optimised filament winding system for hydrogen tanks which retained the high-precision capability that we applied from our higher-end filament winding machines from very demanding customer applications.

We’ve delivered many AFP and ATL systems and improved their performance continually. Our latest AFP and ATL systems are optimised for easy access and maintenance and even for lab environments. They have the multi-material capability and advanced layup models for thermoplastics or head-exchange capabilities. In addition to the industries where we’ve delivered machines, aerospace is increasingly interested in our solutions as they seek to increase ROI, retain flexibility of their CAPEX with selective upgrades of the equipment. The automotive sector is also looking into high-volume automated production of serial parts.

Q) Is there a particular customer product or application that really stands out and gave you a lot of satisfaction?

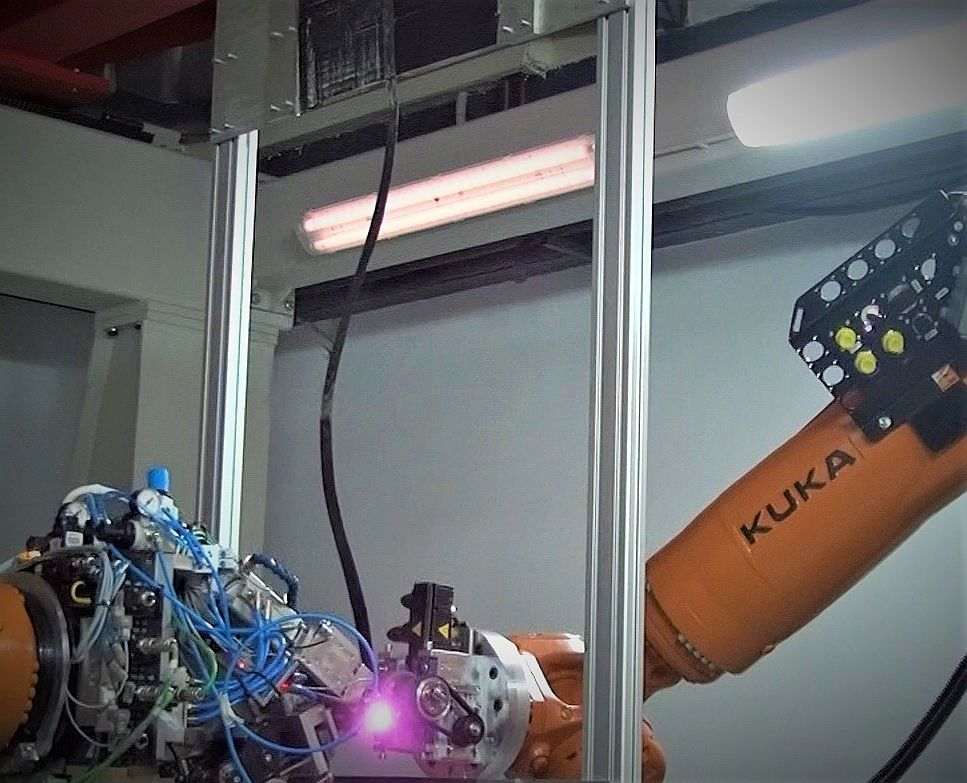

What stands out recently for us is our first Dual Robot-cell for ‘tool-less’ thermoplastics layup. We used our compact and proven ATL systems and designed a supporting robotic-head on the other side of the ATL head. We were able to achieve in-situ consolidated thermoplastic 3D parts from something that started as only a paper-napkin idea. In fact, it took some time for this technology to become public since it was initially tried, because we were under a non-disclosure agreement.

This advancement put Mikrosam at the forefront of a lot of development work in pushing more thermoplastic parts for aerospace and automotive industries. We’ve been making very complex trials in cooperation with a number of OEMs, using our AFP and ATL methods to fine-tune the thermoplastic layup models and achieve superior in-situ consolidated parts. We’re proud of this recent example, which demonstrated that Mikrosam is a technology-based company in pursuit of widespread use of advanced composites.

Q) How much consideration are you giving to the implementation and use of automation?

We were one of the first filament winding suppliers with automated lines: the first large-scale LPG and CNG lines for automotive. Today we’re in the design stage for one of the largest automated production lines for CNG and hydrogen tanks. We’re also working with an automotive customer on prototyping large-volume thermoplastics production lines. Our engineering and technology focus and our flexibility is what customers need when they decide to move technology from lower-volume high constraint cycles to higher-volume markets while retaining quality in production.

Our strength in these areas comes from our dedicated large software team with extensive experience, not only in our own software, but also for integrating multiple units - even non-Mikrosam equipment - together in a single total control system. Here we have introduced couple of innovative solutions in automation of different process that were previously done manually (e.g. our patented fibres cut and restart solution).

Q) What are the main focus areas of your current R&D efforts?

Our largest R&D efforts are in thermoplastic in-situ consolidation for aerospace and automotive, as well as improving cycle times for automotive in fuel-cell vehicles. We tie this to our software team, which is tasked with ensuring the technology is easily available when fully tested and optimised. In thermoplastics, we were the first company to produce a tool-less layup of 3D parts using two robots. The benefit from this technology was our ability to integrate a multi-robotic cell as a single unit in production of complex composite parts. Additional focus of R&D involves our in-process inspection systems to improve layup quality for complex parts and improving the cycle times for automotive applications. We hope to lead with advanced composites in higher-volume industries.

Q) What do you feel are the most important assets of a company?

It's a combination. For us, being located in Macedonia - and the fact that we count among a very small group of peers and competitors globally - is a source of pride and constant motivation. Granted, we don't enjoy many of the benefits that our competitors have enjoyed, such as state sponsorships, access to public or private-equity financing, proximity to large OEMs, publicly-funded R&D programmes, etc. We’ve been able to sustain our business with a strong customer-focused strategy and continual investment in our engineering community.

Q) What kinds of machine tool developments will we be seeing in the future?

To push more widespread use of advanced composites, lower-cost machines, integration, and higher-quality with faster cycle times will continue to be the drivers and challenges. We’re seeing it in aerospace where the desire to increase production rates means finding newer or lower-cost methods of automation. There is also a demand to improve cycle times whilst retaining quality in cases where the production process is more mature.

Q) Where do you see the biggest business challenge coming from this year?

The machine tool business is a long-cycle business. Therefore, deliveries aren’t always impacted, but new work in the pipeline becomes an indicator. We’re currently entering the year with a very strong backlog stretching well into 2020 and with a very good order book. We’d be concerned if customer interest starts to slow down or delaying CAPEX decisions, or end-use markets start pushing back start of production dates.

Q) Finally, what differentiates your company from the competition?

We always use what customers say about us. In filament winding, our customers have described us the leading supplier with best ROI on the market. That's why we win repeat business because they know they can rely on our customisation competence to make significant optimisations. In layup, we feel the competition has dismissed us, but this is changing - especially given what the OEMs have said about our capabilities. In AFP and ATL, the feedback is that we provide the most cost-competitive proven systems. We remain one of the ‘best-cost’ suppliers of machinery with a strong after-sales support system.