Latest routers optimised for composites

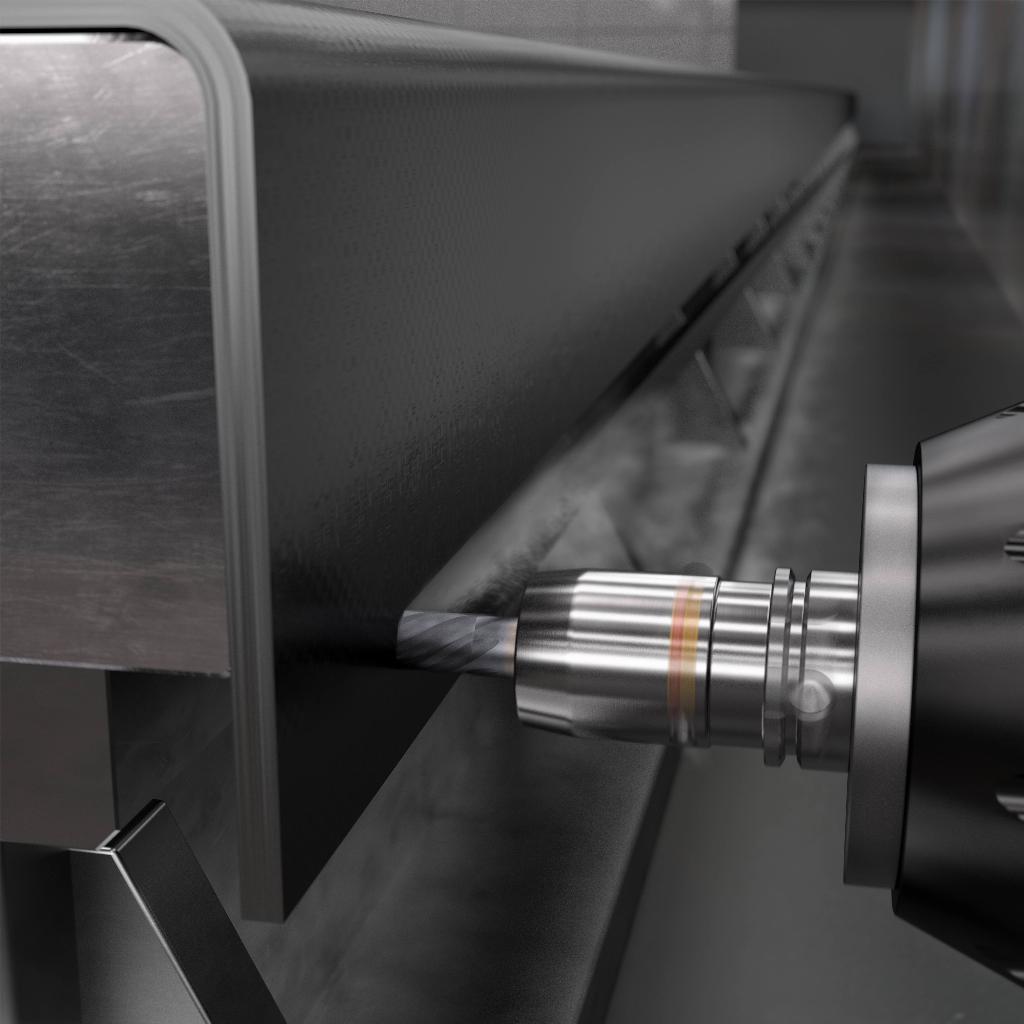

New CoroMill Plura routers unveiled by Sandvik Coromant offer optimised milling and slotting operations in composite materials such as CFRP and GFRP.

Production engineers, machine shop managers and operators will all benefit from the patented geometries provided by the new routers, particularly those in the aerospace industry, where these materials are increasingly prevalent, as well as others in sectors such as automotive, motorsport, wind power and marine.

Machining solutions dedicated to specific composite materials are becoming an increasingly important factor at machine shops looking to achieve improvements in quality, cycle time and costs. The abrasive content of many composites causes issues such as rapid tool wear, compromised cutting quality, elevated temperatures, vibration and unstable cutting conditions. With these challenges in mind, the latest CoroMill Plura generation from Sandvik Coromant has been developed to improve CFRP and GFRP machining on 3-, 4- and 5-axis CNC machining centres, as well as gantry-type CNC machines and stand-alone robotic arm systems.

“The CoroMill Plura brand is long-established and proven throughout industry, and with this latest generation of routers, patented geometries have been designed specifically to boost the machining of composite aerospace parts that include fuselage, wings, stabilisers, stringers, spars, ribs, frames, substructures, floor beams, struts and pressure decks,” says Aaron Howcroft, global product manager composites, Sandvik Coromant. “The routers offer high productivity and have the longest tool life on the market. Furthermore, they are available as standard items for fast ordering, thus delivering benefits to procurement/purchasing teams.”

When milling and slotting composite materials, the new routers are used primarily in full radial engagement and at full depth of cut. In some cases, finishing passes can also be deployed. Helix angles have been carefully designed for ideal sharpness and cutting edge strength, thus ensuring longer tool life and high-quality surface, edge and slot finishes. The range comprises three cutters: the CoroMill Plura compression router, CoroMill Plura low helix router, and CoroMill Plura serrated router.

The CoroMill Plura compression router, with its dual 40° helix, works best with special woven glass layers on both sides of CFRP components. As there is an overlap between compressed flutes, the router performs well in thin, flat materials by reducing material vibration.

Specifically designed for smooth and burr-free finishing passes in CFRP workpieces, the CoroMill Plura low helix (5°) router features a high number of teeth and a coating that is designed to aid quick cutting and protect from heat. Right and left helix options allow flexibility in material with challenging support conditions, such as weak or compromised fixturing.

Finally, the CoroMill Plura serrated router, with its large flute form, allows for very high material removal rates. The geometry also offers a dual cutting action to reduce delamination and vibration, ultimately providing a single-pass solution to minimise stress on composite parts.

All three CoroMill Plura routers can be used with or without coolant.

www.sandvik.coromant.com/en-gb/products/coromill_plura