Hydrogen tanks and the filament winding process

Roth Composite Machinery examines the future machine concepts of producing hydrogen tanks for the mobility sector by using the filament winding process.

New power train technologies based on hydrogen or natural gas, for example, are gaining more and more importance for resource-saving mobility solutions. For the economic storage of these fuels in vehicles, pressure vessels of type IV are suitable. They are based on a thermoplastic inner tank, also called liner, reaching the necessary pressure stability by fibre reinforcement using the filament winding process.

Type IV pressure vessels are characterised by their tremendous lightness and safety and are thus highly interesting for numerous applications in the mobility sector.

Roth Composite Machinery says it has the necessary expertise and experience in the development and building of machines for the manufacture of such vessels. Plenty Filament Winding Plants from Roth are used by all market leading manufacturers producing pressure vessels for gases worldwide. Each production line is planned and designed to precisely fit the requirements of the customer's application. The advice given by the machine builder includes the sequence of single production steps, the material selection and processing, the automation level as well as the increase in productivity up to the commissioning and instruction in the operation of the production line.

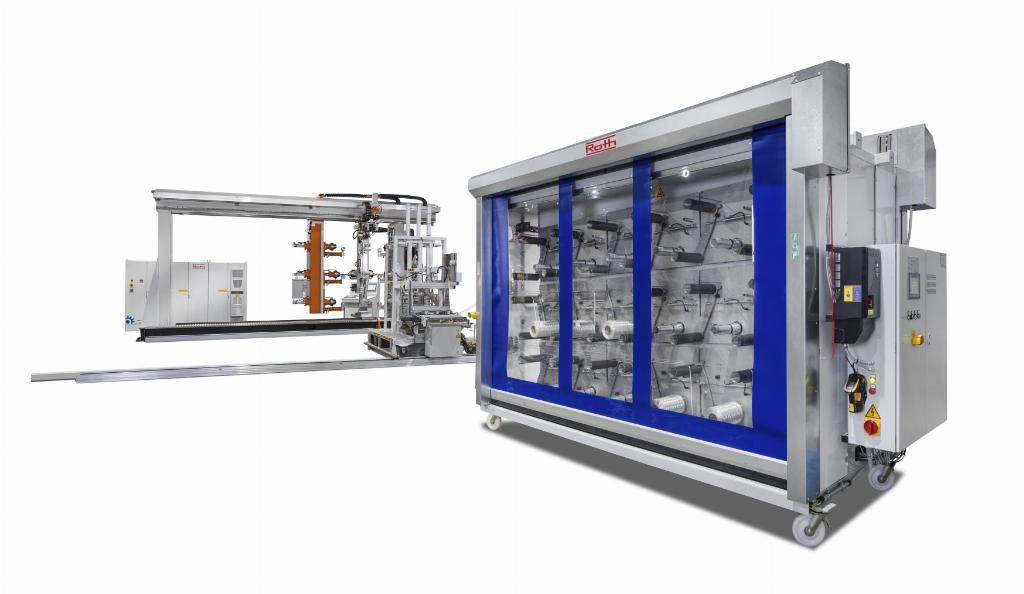

Roth Composite Machinery has recently delivered a customised Filament Winding Plant for the manufacture of hydrogen tanks with three spindles.

Dr Andreas Reimann, general manager of Roth Composite Machinery, explained: “A high-performance drive concept combined with a new machine frame structure enable performance improvements of about 40% compared to the international state of the art.”

The machine concept comprises five interpolating axes and additionally five CNC programmable axes. The set-up of the machine is suitable for series production as well as for development applications (R&D) using the traditional wet winding process. Through separation, the impregnating station enables an individual use of single spindles in order to avoid unnecessary consumption of resin.

An NC-controlled doctor blade allows a precise and reproducible adjustment of the resin gap. The movable impregnating station is suitable for the processing of carbon fibres as well as for glass fibres and reduces the roving load due to decreased wrap angles. By means of the fibre storage device, even very low fibre tensions can be adjusted in line with the process due to the double cylinder control. Constant fibre delivery speeds of up to 4.5m per second can be realised.

The production line is prepared for a quick and easy change to the Towpreg winding procedure. Through the use of the Roth RCA (automatic roving cutting and applying device), the automation level of the machine is increased. For the winding of pressure vessels, for example, the machine is equipped with an automatic pressurisation and pressure measuring system which is able to create and regulate the necessary inner pressure of the liner during the winding process. The exceptional machine stiffness minimises mechanic impact on the manufacturing process and ensures highest precision during the filament winding process.

When using Filament Winding Plants of Roth Composite Machinery, production processes in the traditional wet winding procedure as well as Towpreg applications are possible. For the described production line, Roth Composite Machinery has further developed the spool fixtures at the spool creel – they facilitate the placing of full spools as well as the removal of empty sleeves. A CNC controlled counter bearing guarantees the exact positioning when changing the setting, saves set-up times by this and can compensate length deviations of the plastic liners within the tolerance range. The clamping pressure of the sleeves is adjustable by proportional valves via the program.

The new Filament Winding Machine is versatile in its design – it can be used for small light components as well as for large heavy parts and thus offers a wide scope of production.