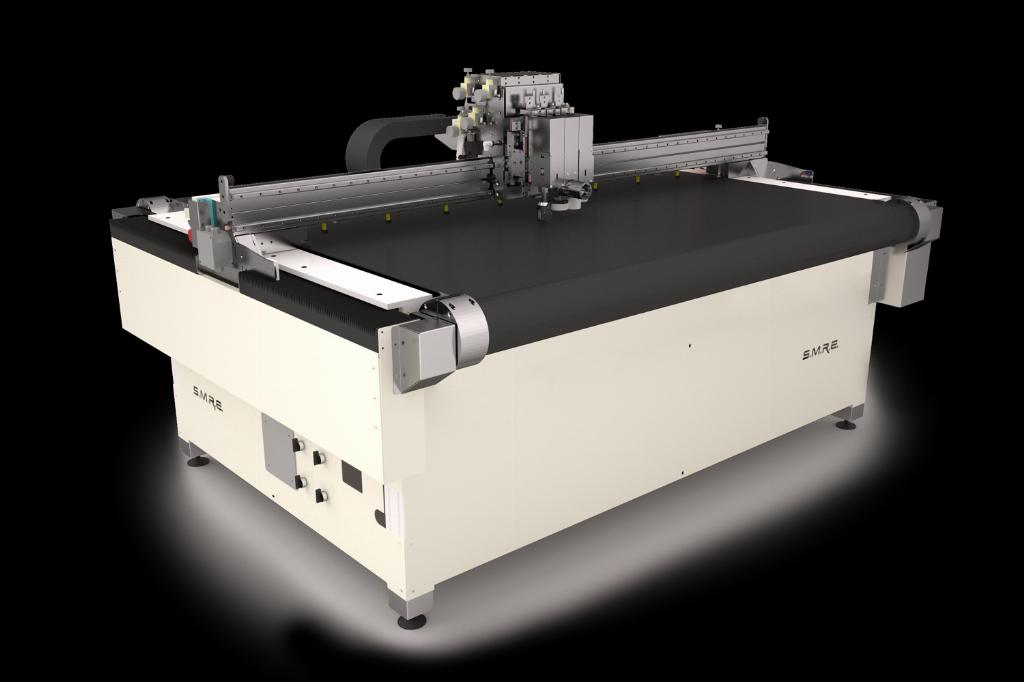

Your flexible flatbed cutting friend!

In our Q&A session, Composites in Manufacturing hears the views of flatbed cutting specialist SMRE’s sales manager, composites & heavy duty, Matteo Bartolini.

In our Q&A session, Composites in Manufacturing hears the views of flatbed cutting specialist SMRE’s sales manager, composites & heavy duty, Matteo Bartolini.

Q: What are the types of demands placed on your company by today’s customers?

SMRE is renowned for tailoring productive solutions to fit its customers’ requirements. We have an extremely wide range of machines but we never miss the opportunity to go the extra mile and give customers what they actually need. So, ‘flexible’ is a good word to define us, our attitude and our machines. The after sales service and the good relationship we are able to build with our customers are also crucial to our success.

Q: Latest trends: what is driving flatbed cutting machine technology and what are today's customers looking for in terms of performance solutions?

All customers need speed and precision. The machines they look for need to be fast, to streamline their production, and the parts they get need to be flawless, in order to avoid having to finish cut by hand. In some cases, customers also need to cut series of pieces with the same shape and same dimension, so repeatability is crucial too. All this can be achieved by good cutting machines.

Q: Tell me something about the flatbed cutter machines you supply?

We have installed many machines in the UK over the last few years in multiple industries. Our machines cut fabrics, cores, sandwich panels, non-wovens and many more materials. We have developed our own CAD/CAM software, whilst component nesting is currently outsourced.

In terms of after sales support and machine training provision, our technicians normally spend a few days after the installation providing proper training to the customer. The after sales service is granted worldwide, either by our distributors where we have one, or by SMRE’s technicians. We can also provide remote after sales service on the software by means of an internet connection.

Our machines are suitable for any company that needs to cut composite materials. Our customer base ranges from the automotive to aerospace industries, and from wind power generation to military applications. The application fields in which our machines can be used are many and extremely diverse. Sometimes we get customers enquiries from unexpected industrial fields. Whatever needs structural strength, rigidity and lightness, as a principle, can be built with composite materials. If you just think of the potential, you could use composites for the production of an infinite variety of objects.

Q: Do you get involved in supplying/specifying automated roll feeding of dry fabric/prepreg material equipment to the machine’s bed?

We manufacture semi-automated fabric feeding systems, these are standard products for us. So much so that some of our cutting plotters are supplied just together with a multiple roll holder with a semi-automated unwinder/feeder. We have designed fully-automated feeding systems in the past.

Q: Without breaking any NDAs/customer confidentiality, can you say anything about customer success stories and the sectors in which these customers operate?

One of our customers manufactures army helmets. The challenge in this project was to cut quite heavy dry ballistic Kevlar. We had to study the features of the material in order to define which cutting technology was the most suitable to grant cutting precision and good cutting speed. Since Dry Kevlar is a breathing material, the vacuum turbine wouldn’t work to suck the fabric down on the cutting surface. We also needed to understand how to keep it stuck on the surface as the blade cut through it. Needless to say, we found all the solutions and the customer has been cutting his Kevlar beautifully for over a year now.

Q: What differentiates your company from the competition - why should a customer use you over your nearest rival?

Flexibility. Our competitors are generally stricter about what they want or don’t want to do. We work differently, as I mentioned above, we try to understand our customers’ needs and turn their ideas into a machine. Besides, since we have been operating for nearly twenty years in numerous different industrial fields, we’re experienced in the use of almost all of the cutting technologies currently available on the market. This gives us a wider array of choices when it comes to finding the right cutting technology for a specific material.

Q: How do you see the future of the composites manufacturing industry evolving and particularly subcontract kit cutting evolving in the future?

Q: Where do you see the biggest business challenge coming from this year?

Our challenge for this year is to increase our brand awareness in the composites industry. We are winning the trust of more and more customers, and we already have a nice list of references to witness our efforts and the good job we provide.

Q: How important are tradeshows like JEC World to your company and has this year’s edition been a success so far?

This year’s edition of the JEC World show has been a success and we received many more visitors than we expected. Exhibitions like JEC are important especially in a product launching phase - like our SM-381-TA machine. JEC, like other good events, are priceless opportunities - not only to find new customers, but also to start collaborations and to understand what are the niches of the market that others haven’t explored.