Evolving through innovation

Mike Richardson catches up with Matthew Tillett, commercial sales manager of flatbed cutting machine specialists Blackman & White (B&W) to hear how the company stays at the cutting edge of an increasingly competitive industry.

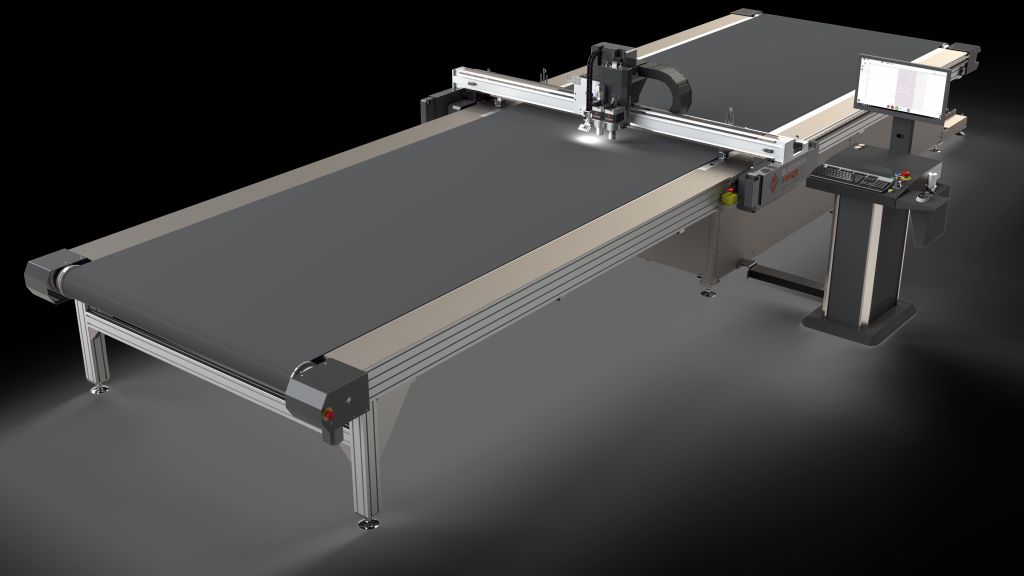

As the UK’s only manufacturer of flatbed cutting systems - and with all machines designed and manufactured from start to finish at its Maldon, Essex factory, Blackman & White remains a family-owned company. Originally founded in 1964 by engineers Jack Blackman and Les White, the company’s machines are renowned for their robust and reliable build quality, which goes hand-in-hand with their record for quickly delivering a return on investment.

“Opening our demonstrations and training centre at the start of 2021 has proved to be a real game-changer,” begins the company’s commercial sales manager, Matthew Tillett. “Having detailed conversations about new applications and production runs with the customer in a manufacturing environment was a rite of passage that we are pleased to of outgrown. The quality of service we can now provide our customers has increased tremendously. Offering over three B&W demonstration machines for trials and tests allows our customers to leave with all their questions answered and a clear understanding of our true capabilities.”

Whilst kit cutting is one of its strongest sectors, B&W has increasingly found companies diversifying into several others as well. Tillett believes this is down to the current climate, where sourcing products from independent manufacturers is preferential.

“Historically we started with sailmaking and marine applications, and it’s encouraging to see growth within that sector. Thanks to our diverse tooling range we cover a wide array of materials, including glass fibre, carbon fibre, Kevlar, Nomex and thermoplastics. Having our 200W laser mounted directly next to two interchangeable tool slots provides a solid platform to cover all materials and applications. Most composite customers have a mix of our trusted drag and oscillating tools with our 2.5 or 3.6kW water-cooled routers, which are all automatically calibrated for automated production.”

Independent’s day

I’m interested to know what the customers’ reasons are for specifying a new flatbed cutting system? Is it because of an increase in volumes, a need for faster production throughput, quality requirements, accuracy or a combination of these elements?

“All of the above, but every customer is different and has their reason for purchasing our systems,” states Tillett. “The biggest trend we see is the support from the manufacturing community in seeing the value in an independent manufacturer who can truly design and build something bespoke and solve individuals’ problems. And in terms of the types of demands our customers specify, the bespoke touch is always built into our systems in various guises - from customer blades and creasing skids to customer workflows for customers files - even up to customer parametric designs for some of our clients.”

Tillett says that one of the systems B&W supplied last year proved to be a great success story, as it showcased the work the company has invested into hardware performance, software interface and infrastructure to ultimately push it ahead of the competition.

“Progressive Technology Group selected Blackman & White to manufacturer a new cutting system in line with its new cutting-edge facility,” he explains. “Progressive Technology’s operations director, Daniel Smith approached us to supply his new facility with a material cutting system. This system needed to be adaptive and flexible to cut a variety of materials in very quick turnaround times. Our sales team listened and understood exactly what they were looking for in order to help take their business forward.

“During machine demonstration’s at our Maldon facility, the Genesis V proved itself in all aspects and scenarios that they could think of, proving itself to be accurate, easy to operate, functional and most importantly quick. The Lite digitising system was also a crucial element in Progressive Technology’s choice, as it translates templates and file formats quickly, reducing any potential bottlenecks in the material-cutting process. As our manufacturing and servicing is both UK-based, we were able to offer quick turnaround and response times for routine servicing and breakdown should it arise, which is critical to keeping their business operational.”

Agility delivers benefits

I ask Tillett whether the pandemic-enforced downtime has enabled B&W to reset and look at how efficiently it runs its business - and also the particular aspects that have helped it get through these recent tough times.

“It’s our agility that has worked well for us when the pandemic first hit and uncertainty was in the atmosphere,” he states. “Continually making modifications to our machines, plus just being upfront and honest about what we do and how and when we can deliver is always well received. We couldn’t claim to have experienced much downtime, but the lack of external visits and networking did allow us to finalise a lot of our internal development.

“The key development being our new drive system, which pushes the Genesis V system above the comparable models in the market regarding cutting time and optimisation of how the parts are cut. The future for us will be based around the flexibility of tooling and machine specifications, with rapid innovations in materials creating a push for new tooling additions and chassis sizes. We certainly plan to ensure our agility remains.”

According to Tillett, B&W’s next step will involve relocating to a larger facility to house all its manufacturing, service, support, development, and sales under one roof. He also acknowledges that without its clients, the company wouldn’t be in this position to grow and continue supporting them.

“Blackman & White is a family-owned company and has maintained a profitable business for over 50 years,” he concludes. “We pride ourselves on customer support and value for money with manufacture and design completed in-house.

“We recognise that customers often require a solution that isn’t supported by our competition and due to efficient design processes, we are able to supply bespoke solutions to our clients. We have a programming team that is able to integrate the system into existing workflows and constantly innovate. With a proud heritage of customers and continual improvement our systems are ‘class leading’ in the industry.”