Ever onwards, ever upwards

Mike Richardson met with Pentaxia’s production director, Adam Norris during the recent Farnborough Airshow to hear about the company’s move to a new facility and its use of CMS Industries’ CNC machine tool equipment.

As a family-run, privately-owned company, Pentaxia has deployed a dynamic approach to its investment strategy, expansion and growth. Without the restriction of a multitiered expenditure approval process, it has been able to react quickly to any new business opportunity.

And so it was that in 2017, the company decided that its existing manufacturing facilities in Derby could no longer meet the needs of its customers in the advanced composite market. Whilst moving to a new facility three times as large seemed like a challenging decision at the time, Pentaxia believes it is now starting to pay dividends.

Its new site in Alfreton Road, Derby was purchased in August 2017 and since then, a major refurbishment and investment programme has been underway - reaching a point when staff finally moved in during January 2018. In a move that involved over 120 staff and all the production equipment, output levels still had to be maintained. The move was finally completed in April 2018, and according to Pentaxia’s production director, Adam Norris, it’s been a real challenge in keeping to its production targets.

“Moving to a new facility is very similar to moving house, just over a longer period,” he begins. “We completed the sale, took over the unit in August 2017 and started moving our machine shop department in October, moving one machine at a time. The final piece of the jigsaw was completed around January this year when we finally moved everyone in. Throughout this transition, it’s been a challenge to maintain our production targets and we’ve also had the added complexity of re-certifying some of our aerospace parts via first article inspection reports. We planned around the move by increasing production at our old facility towards the end of last year and this enabled us to move and maintain continuity of output.

“We’re now fully settled in and have reached a platform where we can start inviting our customers to the new facility. A lack of space at our old facility meant that it wasn’t a very lean process. Our new facility is laid out in the way that we want things done and we have now created a more efficient workflow.

One pie, many slices

Pentaxia firmly believes in the importance of spreading its capabilities across several sectors to the point where it now enjoys a wide customer base. The company is purposefully spread across motorsport, aerospace, automotive; it’s trying to keep all these slices of the pie equal. Pentaxia’s workload breakdown comprises 25% tooling production, 25% motorsport and F1, 25% aerospace – which it is looking to grow - with the final 25% accounting for its automotive sector work.

“One advantage of the aerospace industry is that it gives us a solid forward order book. With our headcount, we need a reliable order book and this is the platform that our aerospace business will give us. We’ve seen it with our existing aerospace customers – they are giving us a six-month forecast and this is where we want to be. With F1 we have built some very good relationships over the years with two of the leading F1 teams, and each year they look at larger work packages.

“We have different skill sets within the company, with people with aerospace backgrounds that are more measured, but equally people from F1 backgrounds who like to get things done quickly - it’s a good mix. We now have a new facility and a large amount of equipment that our managing director, Stephen Ollier continually invests in. However, the biggest restriction in terms of growing is the lack of skilled people available. We have customers that want to place work with us, but we can’t actually manage it, so we still have to be quite selective and avoid stretching ourselves too far. To combat the skills shortage, we’ve installed a new in-house training centre using one of our most experienced laminators to perform in-house training.”

Big names, big gains

With a company product range that reads like a ‘who’s who’ of Greek mythological gods, CMS Industries was established in 1969 to provide CNC equipment for a wide variety of markets. CMS’ 3- and 5-axis CNC machine tool range offers high-speed machining applications that cover carbon fibre machining, composite trimming and drilling and honeycomb machining, structural aluminium aerospace components, the machining of stacked aluminium sheet, as well as pattern & mould, tooling and prototype production.

“My background is in CNC machining, so when Pentaxia was first established, I was involved in programming the existing CNC machine tool we were using. At the time, we simply couldn’t afford a CMS machine tool product, so we were using an older machine that we’d retrofitted with a new control. Whenever we attended machine tool exhibitions, CMS was always at the forefront of our minds because their product range includes some very popular machines.

“CMS had managed to market its Ares and Antares CNC machine tool products at the right price point for exactly the right capabilities of what we were looking to achieve, and we were really impressed with what they had to offer. The levels of service it has provided - and the assistance of Graeme Cartwright and Toni Nagiel has been really helpful – after-market support is very important to us.”

CMS’ sales manager, Graeme Cartwright says he is delighted to be working with dynamic and progressive companies like Pentaxia: “Pentaxia utilises our machine centres in a very efficient way and gain the best results from them. We look forward to continuing our strong working relationship which delivers mutual benefits to both companies for many years to come.”

Norris concludes that Pentaxia predominantly uses its CMS machines to machine patterns, jigs & fixtures and large metallic base plates.

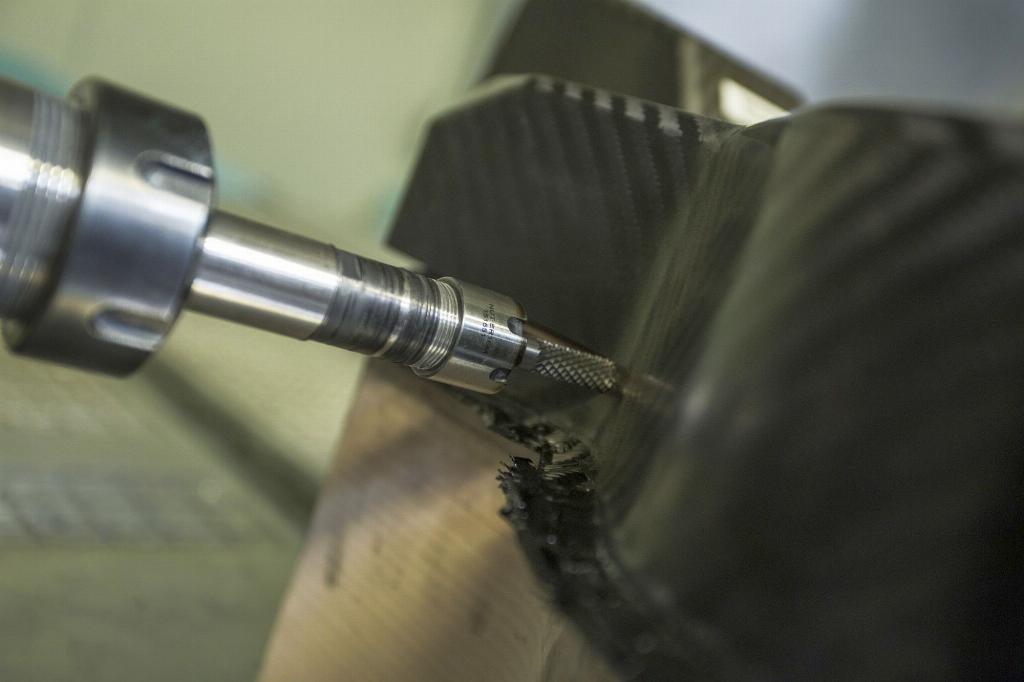

“The CMS machines are phenomenal in terms of the speed and accuracy they provide and are extremely cost effective. We also use them to trim carbon fibre parts. Machining each component has its own challenges depending on thickness and springback, for example. We run all our machine tool programmes through CGTech’s Vericut to simulate all our machine tool codes to understand exactly what it is doing. We are also working with Exactaform, who have provided some great service in PCD cutting tool solutions.”

To adapt a phrase from an old movie, if you build it, they will come. Pentaxia is investing in both its new home and its people in order to be ready for rapid growth and stay at the forefront of advanced composites manufacturing in the region.