EconCore selects MEAF extruder for R-PET honeycomb sandwich panels

EconCore from Leuven, Belgium has chosen the high speed, energy efficient MEAF 50-H34 extruder for its trial production of recycled PET (R-PET) ThermHex honeycomb sandwich panels.

EconCore from Leuven, Belgium has chosen the high speed, energy efficient MEAF 50-H34 extruder for its trial production of recycled PET (R-PET) ThermHex honeycomb sandwich panels.

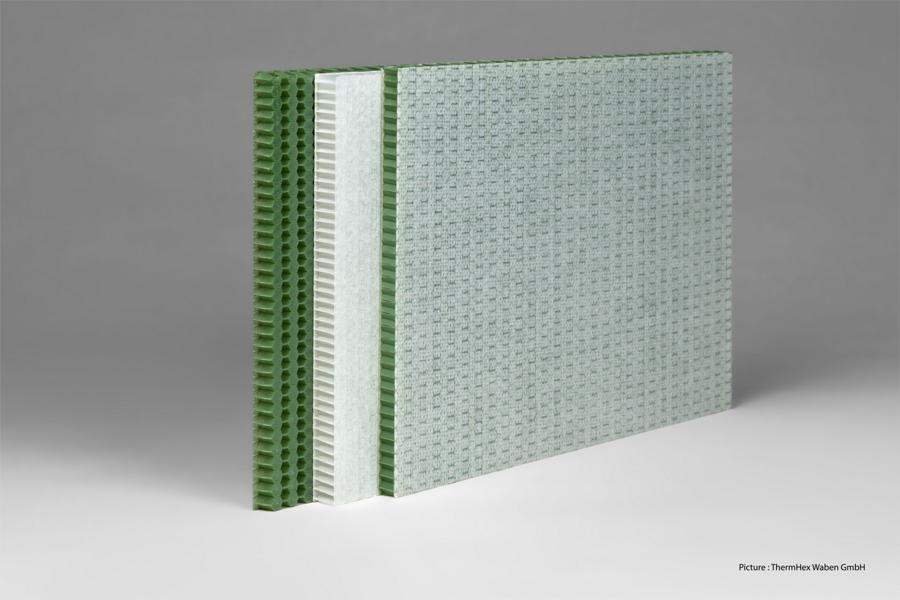

The R-PET honeycomb core is made of 95% recycled post-consumer PET from bottles, combining sustainability with the superior mechanical properties from PET-material. The new extrusion technology will also feature prominently on the MEAF stand at K2019, stand A22, Hall 17.

“We want to bring a smart, innovative and sustainable product to market that contributes towards the circular economy of plastics,” said Wouter Winant, Technical Manager at EconCore. “Our R-PET core offers high stiffness and strength in compression and shear, high temperature stability and has excellent weight to cost ratio. In addition to the CO2 reduction because of the use of recycled material, the R-PET honeycomb core further reduces the CO2 footprint thanks to the lower weight of manufactured parts. Of course, this needs to be produced in a cost-effective way, for which we have chosen the MEAF 50-H34 extruder, as an economical but highly efficient flat die extruder at the start of the production process.”

Added Ardjan Houtekamer, Technical Director at MEAF: “With their high throughputs, extruding up to 1,200kg per hour while using only 0.20kWh per kg, the sheet extruders of this series are currently among the most efficient in the market. Our extrusion lines are ideally suited for both single and multi-layer extrusion applications and can produce up to eight layers, using a range of materials including PP, PS, HIPS, PET, PE, PA, PLA, TPE, EVOH barrier and others.”

EconCore’s thermoplastic honeycomb technology allows for production of honeycomb panels within a continuous and in-line integrated process. During the successive production steps polymers are extruded, vacuum formed and folded into a honeycomb core. This results in a highly cost-effective process, ideally suited for large volume applications. Furthermore, lamination of skin layers is typically in-line integrated with the continuous honeycomb core production, allowing for one-shot production of added value sandwich panels or parts.

The EconCore process can produce both regular flat panels as well as thermoformable ones. The latter type obviously has a broader range of applications, since these panels can be pressed in any required form or shape. EconCore expects that the developed process and R-PET products will mainly be offered to the automotive industry, since car manufacturers are constantly looking for lightweight materials with specific temperature requirements, that can be produced in a cost-effective way. At the same time, the products fit well to other large volume applications, including furniture for instance.