Cygnet Texkimp unveils first commercial, high-volume thermoplastic line

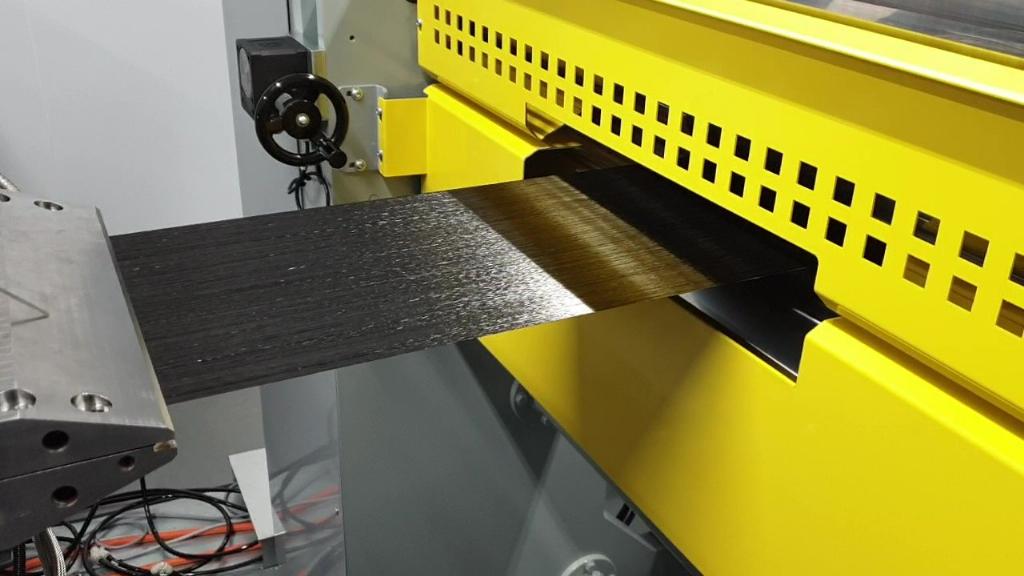

Cygnet Texkimp, the Northwich, Cheshire-based machine builder and fibre converting specialist has unveiled a production-ready thermoplastic line to manufacture thermoplastic tapes in large volumes.

The Direct Melt Impregnation Thermoplastic Line is believed to be the world’s first commercially available thermoplastic manufacturing line capable of using standard polymers, from polypropylene to PEEK, to create high-grade thermoplastic prepregs on an industrial scale.

“For the first time, we are offering the mainstream industrial markets, including automotive and construction, a workable way of manufacturing thermoplastics efficiently and in high volumes using standard raw materials and secure supply routes,” explained Andy Whitham, technical manager at Cygnet Texkimp.

“We’ve developed a simpler, cleaner, faster, more cost-effective way of manufacturing thermoplastics in high volumes. By using standard polymer in pellet form we have significantly simplified and shortened the process without compromising the quality and performance of the end product. We’ve created a compact machine that can easily be accommodated within a relatively small manufacturing facility and doesn’t require any particular specialist knowledge to operate.”