The composition of a modern composites producer

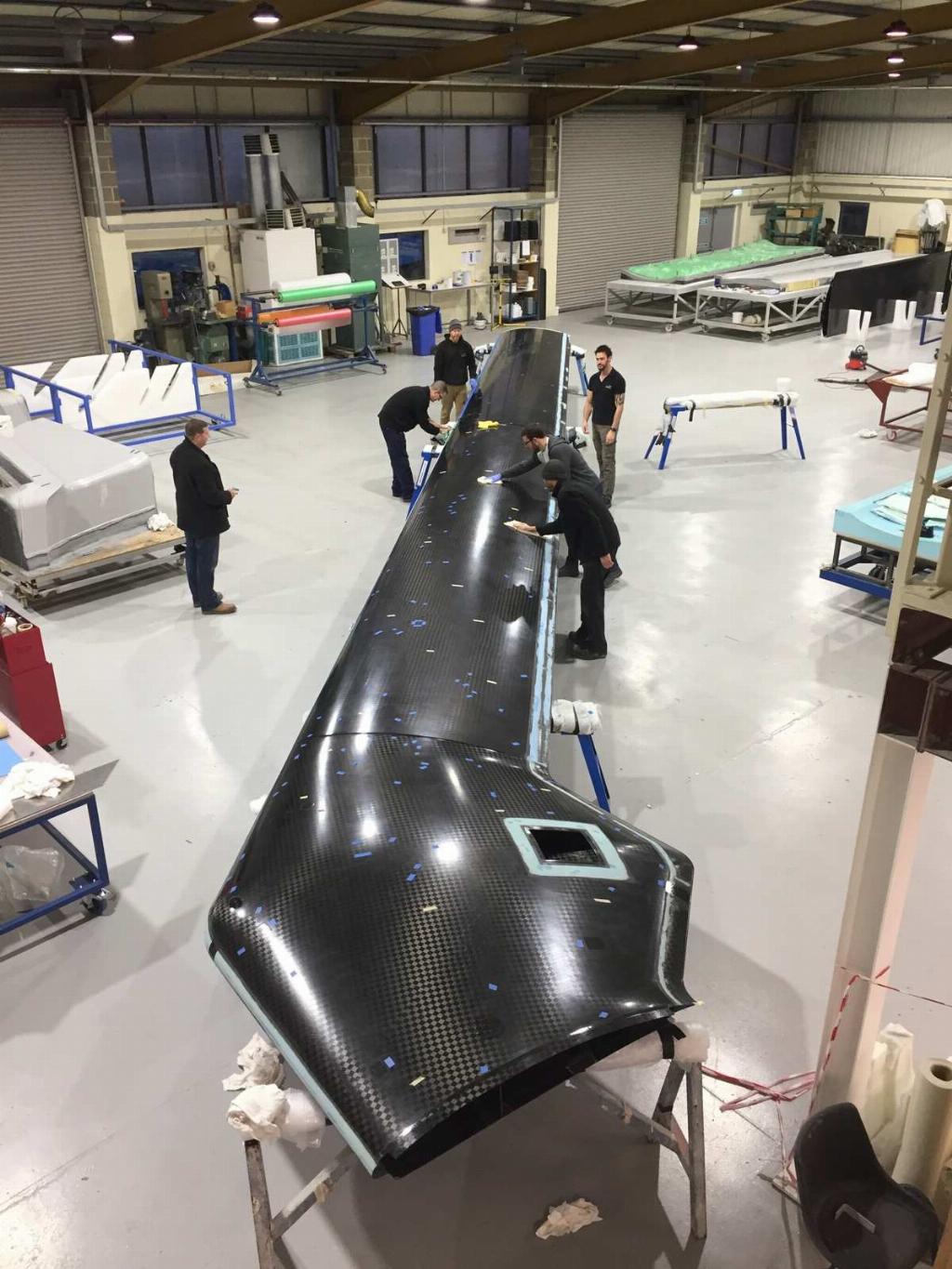

Composites in Manufacturing hears how from modest beginnings, Poole, Dorset-based Norco has expanded and diversified to now offer a wide range of advanced composite and GRP structures for multiple sectors.

Composites in Manufacturing hears how from modest beginnings, Poole, Dorset-based Norco has expanded and diversified to now offer a wide range of advanced composite and GRP structures for multiple sectors.

Norco is a leading UK composites manufacturer, specialising in advanced composite materials, out of autoclave processing and large-scale composite structures, employing in excess of 150 people across multiple facilities. The company has three dedicated composite shops, an environmentally-monitored cleanroom for smaller high quality prepreg parts, a CNC machine shop and a paint/spray shop. The company possesses four curing ovens and two autoclaves.

Opened in 2012, Norco’s advanced composites centre is in the process of being extended to around twice its original size with a 10,000ft2 extension. At the same time all existing plant and equipment within the Centre is being upgraded or added to in order to cope with increased demand and larger scale projects. Norco will also have an additional 10m x 6m x 3m spray booth available from 1st April, which will more than double its existing spray capacity.

As part of its growth strategy, over the past year Norco has acquired C&B Composites, expanded its sales and engineering team to provide support to customers and recruited several new positions including a new production manager, human resources manager, quality inspector and a marketing executive.

Norco is involved in a mix of large-scale composite structure projects within the marine, architectural and industrial sectors. For example, it is suppling composite components for a range of modular workboats as part of the MoD’s latest workboat replacement scheme. Many of the company’s projects are development projects and so are protected under industry NDAs.

Keeping pace with change

The composites industry continues to change, placing increasing demands on manufacturers. Customers are constantly looking to push the boundaries of what is possible using composite materials, be that due to aesthetic requirements, weight targets, extreme operating environments or simply to replace alternative materials used in existing roles. The challenge is to provide customers with smart and cost-effective solutions that demonstrate Norco’s flexibility and approach to customer relationships. Many enquiries received are for incomplete designs which require an engineering input to devise the required solution. This can often be a benefit as having a manufacturer involved with the design of a product can improve its manufacturability and reduce part price cost. For Norco, providing a solution to a customer helps build the business relationship and can lead on to future projects.

Lead-time is a critical factor in manufacturing and Norco can take a concept design and quickly turn it into a fully-finished product. Once the final design is signed-off, customers typically want the parts as soon as possible and being able to deliver tool design, tool manufacture and part manufacture really makes a difference for customer confidence. The Norco team is challenged on a daily basis by customers to develop new and innovative ways of using, processing and integrating composite materials. The company believes every member of staff has a part to play in understanding existing processes and methods, evaluating the limitations of a particular process, material or product, and then proposing the next step towards a better product for customers. All projects are tightly controlled using a project manager to work directly with the customer as a constant point of contact, thus reducing the potential impact of miscommunication between the two parties.

Despite the continuing uncertainty over Brexit, Norco has seen a growing demand for composites in the aerospace, marine, automotive and defence sectors among others. There are new types of projects being delivered and new opportunities to work with companies on complete re-design projects for structures previously built in other materials. In particular, the company has seen a significant increase in the requirement for composite bodywork and interior panels as part of its automotive work.

Offshore manufacturing is recognised as a genuine threat to the UK and will always be difficult to compete with on price due to running costs, worker pay rates and land costs in other countries. However, Norco has found its customers are generally looking for a different type of service from that of most large scale offshore manufacturing facilities. Often with its input and experience in the composites industry the company can provide the key to the success for customers’ projects, so there is little incentive for them to consider overseas manufacturing. Many customers want to see where their products will be manufactured and the ability for that customer to come on site part-way through a build is something that is very appealing. In addition, with many of the large structures Norco manufactures, the process of shipping the parts to the UK offsets any cost savings gained from having the part manufactured offshore.

Capabilities that count

To continue bringing products to market, Norco needs to address barriers, such as suitable facilities and design capability. With modern composite processing techniques, plant and equipment can be one of the major limitations. As Norco builds larger structures, sometimes with a greater degree of accuracy, tooling and structures often need to be made in fewer individual pieces. The ovens, autoclaves, access equipment, cranes and general plant are frequently used to their full capacity, and even modified or upgraded for specific projects. Also, there is now a greater customer dependence on suppliers to produce more drawings of both part design and tool design. As a result, Norco has invested in additional CAD software, to allow the company to more easily share files with customers.

Within the composites industry, infusion and out of autoclave prepreg composites are currently in demand, as is large carbon tooling at a lower cost from the traditional epoxy tooling block. Norco has successfully infused large, highly accurate carbon tools from machined paste patterns, and the tooling can then be used in an autoclave environment.

With regard to the future, Norco sees its biggest challenges in the form of managing further expansion, recruitment of skilled personnel and maintaining the quality of training and service currently available. From a process perspective, the company is keen to promote its autoclave capability and the fact it can now produce quality autoclave cured tooling and parts.

Norco has come a long way in its 30 years. The composite industry offers significant potential for new products and manufacturing techniques and it is ideally suited to take advantage of these. In being able to accommodate a wide variety of different composite production methods, Norco always offers customers the most appropriate solution for their products. With the right combination of people, leadership, equipment and on-going investment in development of all areas of the business, the future for the company is exciting.