Joined-up marine solutions

In this Q&A session Jon Evans, application engineer at composite software developer CompoSIDE, talks to Ed Hill about its use for marine applications.

In this Q&A session Jon Evans, application engineer at composite software developer CompoSIDE, talks to Ed Hill about its use for marine applications.

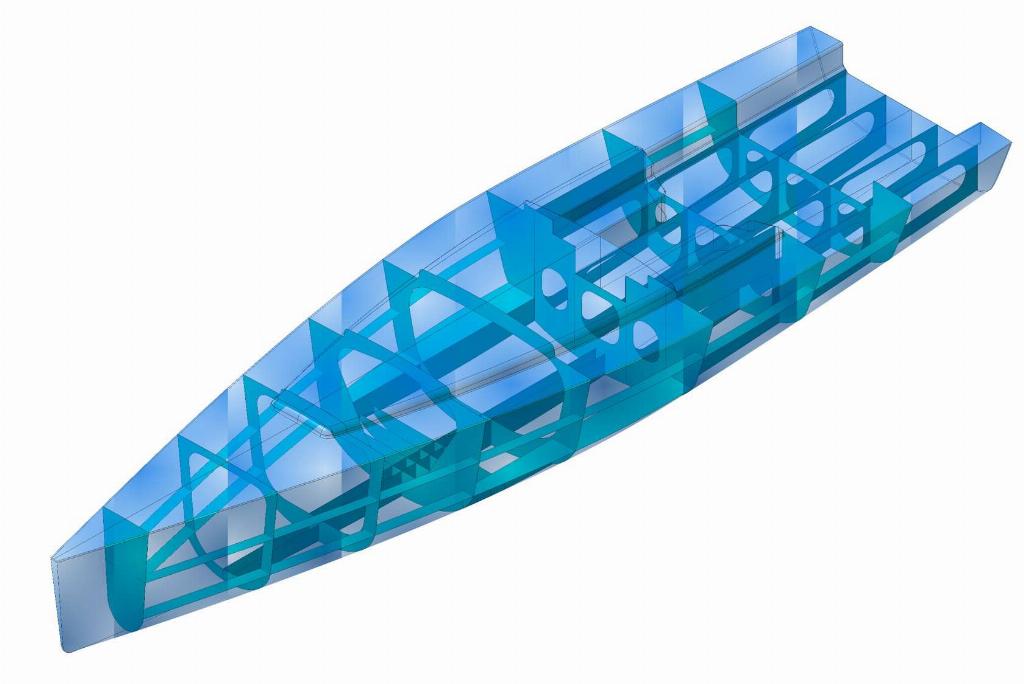

A great deal of time and expense can be wasted early on in the design phase for marine projects, but through modules such as YachtScant, CompoSIDE integrated solutions software enables marine designers and naval architects to input materials, processes and design data to produce numerous accurately costed iterations ready for manufacturing.

Q) Can you provide a summary of what CompoSIDE software is and why you decided to develop it?

CompoSIDE was launched five years ago as an extension to sister company STRUCTeam’s core engineering services. Essentially it is an integrated web-based solution that helps users save time, reduce costs and improve efficiency which speeds up the time to market delivery of composites application.

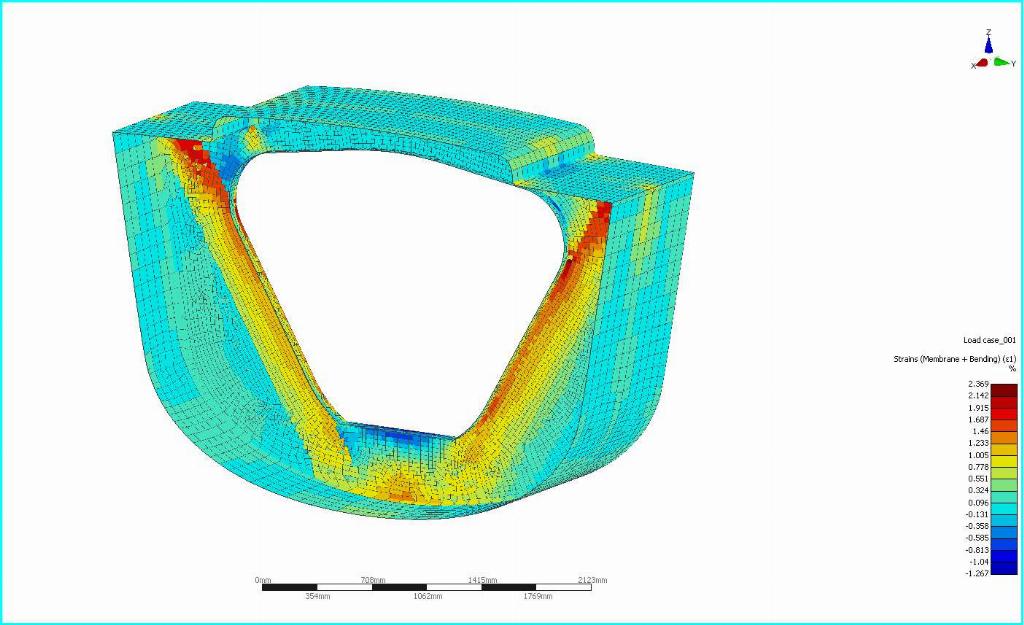

We describe it as a virtual ‘tool box’ dedicated to bridging the gap between complex spreadsheets and advanced finite element analysis (FEA).

CompoSIDE allows for quality improvements through consistent workflows and integrated systems which reduce risk and standardise processes. Alongside a dedicated composites design engineering suite, design tools for using metal and other materials, such as wood and plastics can easily be incorporated. This gives users complete freedom of materials selection and design geometry.

Composites design modules include; materials database, advanced classical laminate analysis, 2D composite beam section, 3D frames, panels and 3D shell design. This allows for more iterations and the development cycle is therefore transparent and predictable.

Q) How can it work well particularly for those involved in designing boats and other types of vessels in the marine sector?

It is a low investment, highly accessible programme and in one platform you can manage all the required design aspects that adhere to DNV-GL and ISO standards.

We have supported the development of boats up to 45m, including multiple racing yachts, cruising and production yachts, and a variety of small to large motor yachts, both commercial and pleasure.

Q) Would you say that as the marine sector is increasingly offering more bespoke or tailored options for customers, this gives designers greater flexibility?

CompoSIDE has been used in the production of one-off and series production boats and motor yachts with varying degrees of technology. This is a real design tool for naval architects. CompoSIDE is more than just a certification device for scantlings, designers can model and analyse structures within the other modules, allowing a high degree of flexibility, and allowing designers to be more confident with structures they design.

Q) How can it help speed up the process from drawing board (CAD model) to final production and what other advantages does it offer users?

CompoSIDE avoids duplication of data, which is inherent to the design of composites, allowing for faster CAD to be created. All the modules within CompoSIDE are linked together, allowing material properties to be linked right through to laminate definition, structural analysis and an automatic bill of material generation tool, which is designed to take into account any factors that affect material usage during production. Laminate tables are also automatically generated, allowing a copy and paste directly from your engineering data to shop floor drawings. CompoSIDE features a full materials database for a huge range of design properties for composite plies, metals, plastics, woods and more. This provides a vast amount of design flexibility to designers who are either new to composites, or those who are working with a wide range of material types.

Q) How does CompoSIDE amass all the data from the manufacturing processes, suppliers, different materials, certification requirements, marine bodies, etc. and how are these utilised?

CompoSIDE includes a large library of materials data, from composite plies and cores, through to metals, woods and plastics. This data is provided for a range of manufacturing processes from hand layup, through to autoclave prepreg processing. This data is used alongside the other modules, to assess a given structure against ISO or DNV-GL certification guidelines. This data can be automatically published in a report which can be used to aid the certification process.

Q) How can the data be shared by all the people involved in the design and manufacturing of a marine project?

Being a web-based platform, all CompoSIDE users can collaborate and work simultaneously whilst drawing on the same source of data. Roles can be assigned, permissions, sign-off rights, budgets, project and task ownership all managed seamlessly. CompoSIDE allows simple navigation within assignments and the dashboard enables users to oversee all project costs. CompoSIDE is totally secure and encrypted and meets ISO/IEC 27001:2013 international standard security certification.

Q) How is CompoSIDE paid for, licensed and managed?

We offer a very flexible pricing structure depending on our customers’ requirements. Quarterly or yearly subscriptions are available. The three types of membership include: Professional Edition for independent consultants and teams of two engineers; Team Edition for structural engineering teams of 3-5 users; and the Group Edition suitable for larger teams of ten. For special situations, we have partnership models as for example with universities and start-ups.

CompoSIDE is available as a 30-day trial allowing users to perform some tasks right away. From our experience we see that the allocation of 3-5 days for evaluation from our client is usually sufficient to demonstrate the capability and assessing if this will deliver within their expectations.

Q) Can you explain more about how CompoSIDE can be used for other design uses aside from marine applications? How do you think it can help the use of composites in industry generally?

Besides the marine scantling module, YACHTScant, CompoSIDE is a composite-dedicated set of tools for any engineer for use in any sector. CompoSIDE has been used successfully in a range of wind, tidal, auto, industrial and sporting applications and is a tool which is suitable for engineers who are new to composites or require something more extensive than spreadsheets but a full FEA package is not required.