CMS forms additive manufacturing machine customer partnership

CMS Italy and Germany say they have forged a strategic partnership with the swissplast group with the delivery of a CMS Kreator Large Format Additive Manufacturing (LFAM) to produce large 3D printed components.

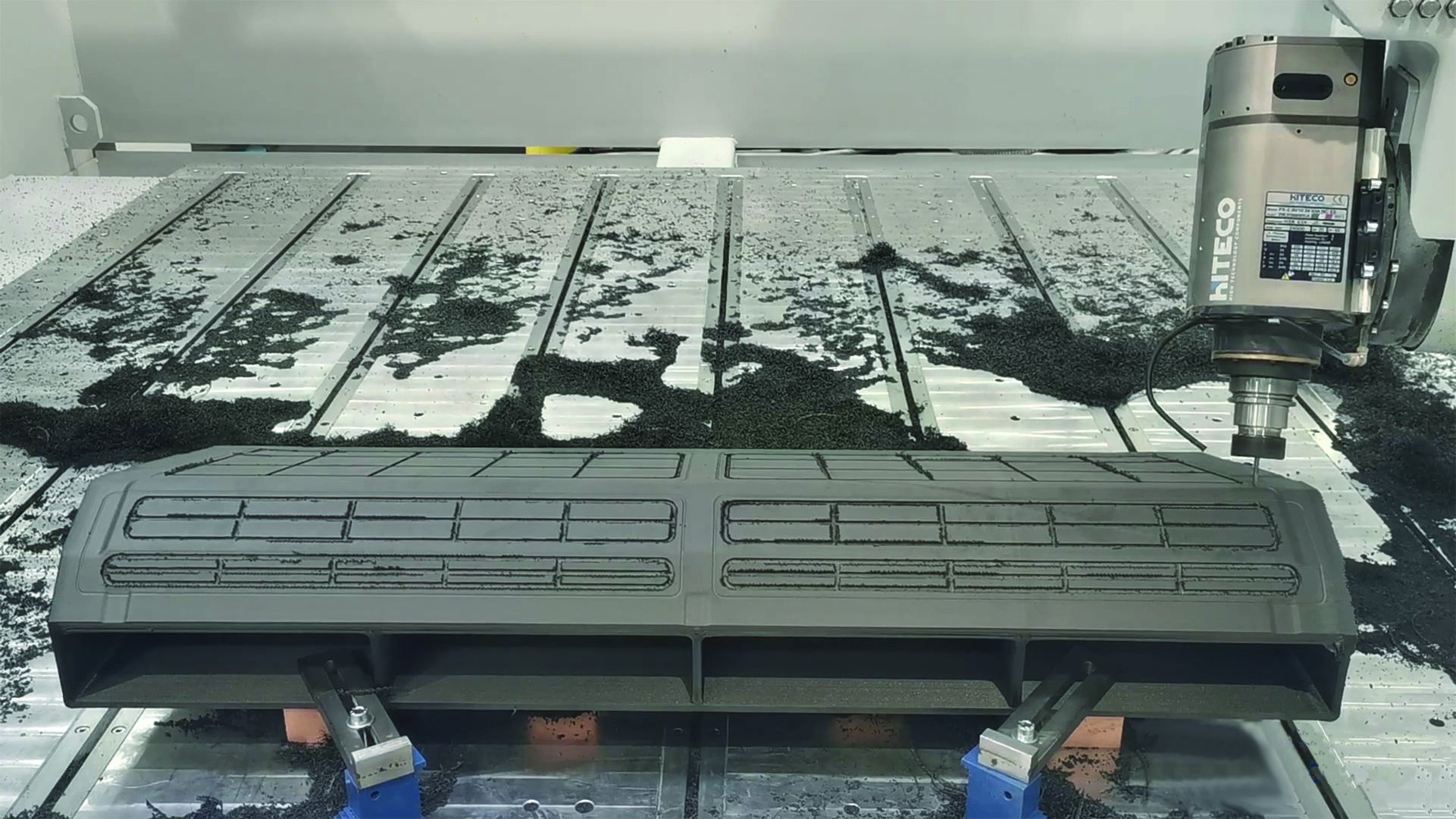

As a leader in CNC machine tools to process composite materials, CMS has worked with the German Fraunhofer Institute to develop a hybrid LFAM machine for the complete integration of a machine tool and large-scale 3D printer. This means it will be possible to create 3D products and then trim them all on the same machine.

The first hybrid machine in the German-speaking region will be delivered to swissplast group in April 2022, making swissplast the first company capable of offering large-scale 3D pieces. From tools to assembly devices right up to production pieces with maximum sizes of 1,800mm x 2,200mm x 800mm will be produced in the future under the brand swiss3Dprint.

The additive manufacturing technology adopted is known as Screw Extrusion Additive Manufacturing (SEAM). Thermoplastic polymer in granulated form is used and the carbon fibre or fiberglass materials tested are PA, PP, PESU, PEI, PET, ABS and Airtech Dahltram.

“Innovation is our top priority,” said Barac Bieri, owner of the swissplast group. “For years we have carefully followed everything happening on the market. With this hybrid machine we have finally achieved a long-awaited ambition. I am proud to say that we are once again in a trailblazing position in the plastic material market by assuming the role of pioneers.”