Cloud revolutionises composite design

When it comes to composite design, the ability to accurately predict the structural performance of a material and the costs involved is imperative. Here we look at how an online cloud-based IT solution is revolutionising composite design, helping manufacturers deliver up to 40% efficiency gains by reducing development time and costs.

Until recently, manufacturers looking for software to help them in the early stages of designing a composite yacht, bridge or wind turbine blade had little choice. There wasn’t a dedicated composite design solution on the market.

As a result, engineers often found themselves cobbling together their own composites IT solution using a mishmash of manual linkages from existing off-the-shelf CAD and analysis software and homemade spreadsheets. Clearly, this do-it-yourself approach to composite design had drawbacks.

Firstly, it resulted in complex and inefficient workflows that required multiple inputs - which often meant cutting and pasting the same data. Second, vital information would often get lost when transferring from one system to the next resulting in inconsistent quality and an increased risk of errors. And lastly, but by no means least, users spent as much time developing these random IT tools as they did on actually developing their composites solutions.

But all this changed in 2010 when STRUCTeam – a composites business and technology consultancy, based in the Isle of Wight – created CompoSIDE.

Julien Sellier, managing director of STRUCTeam and CompoSIDE, explains: “We needed a suitable composites IT solution for STRUCTeam so we researched the market. We had two choices: to link software together using spreadsheets or to use our practical design knowledge and experience to build a purpose-made long-term IT solution to address our needs. Given the gap in the market, we also felt there was also huge mileage in marketing this tool to the wider composite community.”

Dedicated to structures

In January 2015, CompoSIDE was launched as an integrated suite of web-based design engineering modules and data management tools dedicated to the development of composite structures.

Whilst CompoSIDE is said to be the number one composite software for the marine industry - used by world-class yacht designers and boat yards, such as judel/vrolijk & co - it’s also proving popular in the renewable energy and industrial sectors, helping engineers to develop composite parts, structural elements and even complete applications. So how has CompoSIDE revolutionised composite design software?

“Put simply, CompoSIDE is the first online cloud based IT solution of its kind,” enthuses Sellier. “It’s easy to use and reduces the development time and cost for composites applications. It’s got everything an engineer requires for the development of a composite structure – design, project management, materials database, reporting and documentation. The integrated nature of CompoSIDE’s web-based solution means engineers can test multiple design options collaboratively in a very short space of time at the early stage of a project, which ultimately improves the final design solution. A significant amount of time is gained by CompoSIDE combining several analysis types together in its platform.”

Based on STRUCTeam’s project logs, CompoSIDE’s agile design workflow increases process efficiencies by up to 40% by reducing the time and cost it takes to develop composite solutions compared with more conventional methods.

CompoSIDE’s software allows for greater innovation and creativity by letting the user experiment with different designs so during the development of your design, changes can be implemented quickly and the system automatically updates saving significant time and effort compared to using several software/spreadsheets one after the other.

Users can also complete more design iterations for the same time, resources and budget resulting in sharper and more refined component and product designs. And last but by no means least, quality is improved thanks to consistent workflows, standardised processes, an integrated system and a shared knowledgebase.

Another bonus is CompoSIDE’s subscription model, which is based on a flat monthly fee. The baseline package is based upon two concurrent users: an attractive entry point for smaller, but also larger engineering departments. Engineers tempted to try out this new software, can register for a free trial on CompoSIDE’s website which includes help from its support team to get familiar with the interface and share design workflow.

New realms of analysis

So, what do CompoSIDE’s clients think of its software? Chris Matthews, from structural engineering company, Atelier One, says: “CompoSIDE allows us to explore new realms of structural analysis. Being able to accurately and quickly model cross sections of varying material properties helps us explore composite sections in unprecedented detail and easily compare the performance and cost to more conventional solutions.”

How exactly, does CompoSIDE work? To begin with, it’s got an intuitive graphical user interface with straightforward navigation that has been designed specifically for engineers, designers, architects and project managers.

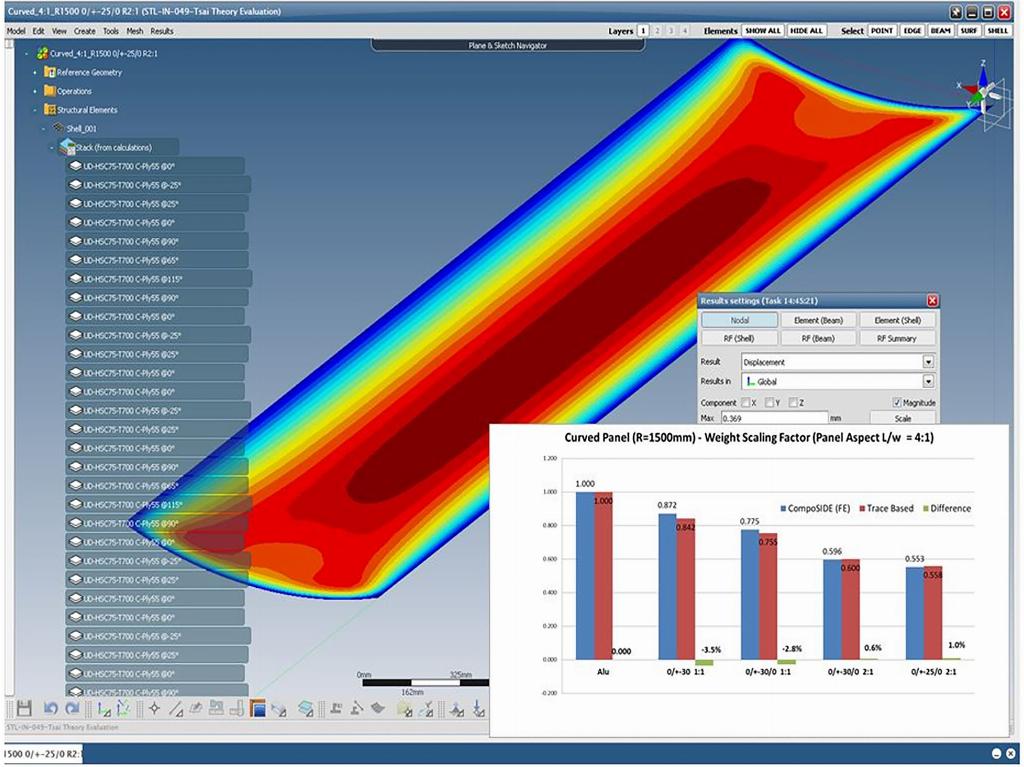

CompoSIDE’s core module provides toolsets for composites materials management, laminate calculation, beam section design and 3D FEA (finite element analysis) modelling with integrated reporting. CompoSIDE also dynamically links design modules and Bill of Materials, which means users are able to update and review the effects of design decisions on BOMs and costs.

The CompoSIDE Materials Database (CMDB) add-on contains 1,200 entries and supports material types like adhesives, cores, fibres, matrix and plies as well as non-composite materials such as metals, woods and plastics, plus you can also add your own materials.

It also features tools for managing materials data, physical properties and mechanical properties, as well as ply generation and micro-mechanics. The CMDB add-on allows export of material and laminates for leading third party FEA packages. Whilst its YACHTScant - a dedicated marine design workflow module - allows the user to develop its design with marine design guidelines such as the ISO12215.

Lastly, project document generation, reporting tools and wizards allow you to create, manage and export your engineering data using customised templates which makes it easy to collaborate with project teams in different locations.

So, if you’re struggling to find an integrated IT solution for your composite design, may be its time to look to the clouds. As they say, every cloud has a silver lining!