Breton unveils new large-scale Genesi 3D printer

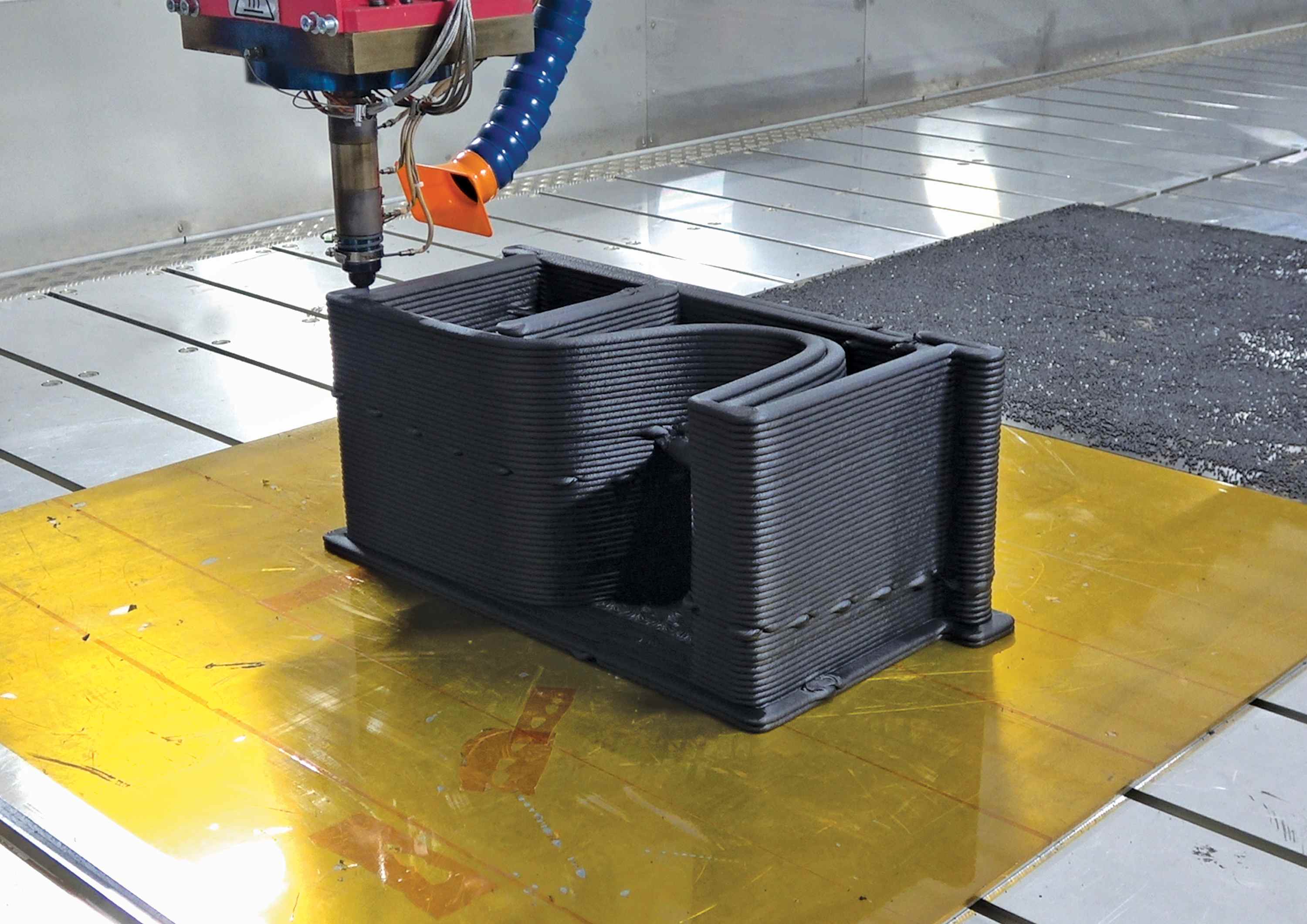

Breton has launched its Genesi 3D printer for the large-scale production of thermoplastic materials. Genesi uses machine learning algorithms and advanced artificial intelligence systems to achieve high-level mechanical and aesthetic properties.

Genesi is said to be one of the world's largest 3D printers for prototyping - 3m in height, up to 5m in width and length on request - with a deposition capacity up to 200kg per hour of reinforced thermoplastic materials.

The intense R&D of new 3D printing systems on which the Breton Institute of Technology has focused in recent years is part of the project co-financed by Mise ‘True 3D printer’. The innovative solution with which Breton opens up a new path for businesses is the result of a process rich in synergies, exploiting the machine learning and artificial intelligence skills of the Canadian company Augmenta, but also all the printing process experience of the MUSP, a research institute in Piacenza.

The development process was carried out in close cooperation with the best material manufacturers in this sector, such as SABIC, and by forming partnerships with strategic companies, such as Siemens in the field of software.

"For a company like Breton, which has always been committed to research and development, it is a pleasure to launch our solution in the extremely innovative and growing sector of 'Large Additive Manufacturing'," said Breton’s business development manager, Gabriele Corletto. "While additive printing is a process that still requires a rather artisanal approach from the user, the goal of 'Breton Genesi', thanks to the development of a complex AI and machine learning system, is to let the machine 'learn' while making the parts in order to shorten the process."

Genesi can operate either in a purely additive version or in combination with a subtractive system. This second solution overcomes the limits of the pure additive method, which allows the production of near net shape parts that are close to the final shape but not completely finished. With Genesi, finishing and optimisation are ensured by the high-speed subtractive capability installed in the same machine, thus making the part not only near net shape but also ready to use.

"For Breton, the partnership with companies is fundamental, as they can re-evaluate the production processes together with our technicians and try out the version available at the Castello di Godego site, which has a printing size of 2,000 x 3,200 x 8,400mm," added Corletto.

The Genesi proposal can be configured with modules of different sizes, with solutions that are adapted to the needs of our current and potential customers.

A partnership has already been established with an innovative start-up, Northern Light Composites, which is using the advantages of Genesi to manufacture the moulds for the prototype of ‘Ecofoiler’, the first sailing boat with a completely recyclable foil on the market. Ecofoiler is a 3.80m hull designed by Matteo Polli with the collaboration of foiling experts such as Matteo Ledri, who has already been involved in three America's Cup campaigns.

Breton invites companies wishing to try out this new solution to visit the company and see Genesi and its advantages first-hand.