AREVO to manufacture world’s first 3D-printed carbon fibre unibody

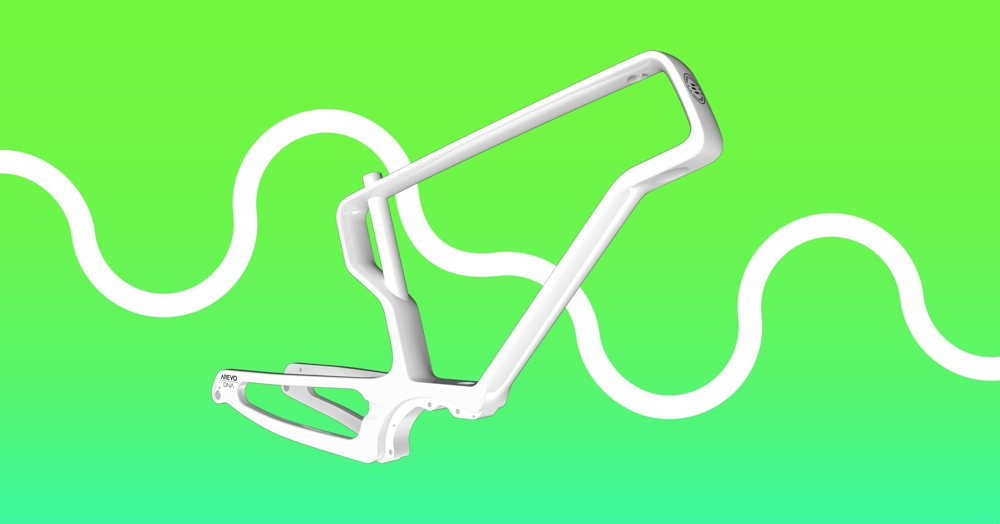

AREVO has announced a partnership with boutique bike manufacturer, Franco Bicycles to deliver the world’s first 3D printed, continuous carbon fibre single-piece unibody frame for a new line of eBikes Franco will sell under the ‘Emery’ brand.

Arevo has announced a partnership with boutique bike manufacturer, Franco Bicycles to deliver the world’s first 3D printed, continuous carbon fibre single-piece unibody frame for a new line of eBikes Franco will sell under the ‘Emery’ brand.

The companies will showcase the new ‘Emery One’ eBike in booth S9 at the Sea Otter Classic bicycling event in Monterey, California, April 11–14, during exhibition hours.

Arevo DNA technology is claimed to be unique in the additive manufacturing (AM) world as it features patented software algorithms enabling generative design techniques, free-motion robotics for ‘True 3D’ construction, and direct energy deposition for virtually void-free construction all optimised for anisotropic composite materials.

Further a unibody bike frame construction uniquely enabled by AREVO technology is setting a new benchmark in high-performance bikes. The Arevo frame is made as a single part, in contrast to current composite frames, which are made of many parts glued together. With Arevo’s intelligent continuous carbon fibre placement, unprecedented structural integrity and stability are achieved. Finally, the Arevo DNA AM process takes the design and final manufacture of a bike frame from 18 months to just a few days at a significant reduction in product development costs.

The frames are in production now at Arevo’s new multi-purpose facility in Milpitas and this achievement with the Emery One represents several breakthroughs for bicycle manufacturers, with implications for other industries as well. These breakthroughs include:

True serial, volume production of AM-made composite parts that are made with thermoplastic materials, which are tougher, durable and recyclable, as compared to brittle and non-recyclable thermoset materials

A replacement of a laborious manual process with a fully-automated, ‘lights out’ production model

Delivering on the promise of localised manufacturing or ‘on-shoring’, which creates greater independence for bike brands

A much greater ‘freedom of design’ for bike manufacturers that creates the possibility of fully-customised bikes made on an ‘on demand’ basis, an approach Arevo calls ‘DESIGN. PRINT. GO.’

“We chose Arevo technology because its iterative and flexible design represents the new age in composites manufacturing, and we wanted to be the first bike company to help lead this revolution,” said Hector Rodriguez, co-founder of Emery Bikes. “Arevo’s continuous carbon fibre technology has been instrumental in achieving the ride quality and high-performance requirements we set out to accomplish with the Emery One.”

Renowned industrial designer Bill Stephens of StudioWest collaborated with the AREVO and Franco teams to design the Emery One bike frame.

“AREVO DNA offers a new paradigm for product designers, it forever changes how we can design and build anything,” said Stephens. “This technology allows us to push design boundaries in a way that was impossible until now. AREVO is changing the paradigm to ‘Manufacturing for Design’.”