A racing certainty for success

Like the fast sports cars it supplies part for, Silverstone Composites uses high speeds to manufacture precise, high quality components within in the shortest possible timeframes. Mike Richardson is quick off the grid to visit the company’s Towcester facility and learn more.

Nestled within the motorsport valley and within easy reach of Silverstone race circuit, Silverstone Composites is a relative newcomer to the UK composites scene. Founder, Marcus Trofimov, has over a decade of experience working in high production environments within the composite industry, and has learnt the value of delivering high-quality components within very tight deadlines.

Using his considerable knowledge in composite component production, Trofimov founded the company in May 2016 to provide bespoke composite manufacturing solutions to the motorsport sector. With the relevant knowledge and capabilities to ensure accuracy and precision for every project, Silverstone Composites ensures that each product leaving its facility matches its customers’ requirements exactly.

“I’ve worked for a variety of composites suppliers over the years and I’ve learnt all their strengths and weaknesses and how their business structures work,” begins Silverstone Composites’ managing director, Marcus Trofimov. “Originally, I worked on the shopfloor as a laminator and learnt all the skill sets required. I then moved into a technical role where I was quoting for jobs, and once I’d learnt all I could, I decided to seek an investor who would loan me the capital to set up my own business.

“Enter investor Anthony White, who has not only played a key investment role, but as a friend and mentor has helped me understand the values of a smart and well-planned business. His advice and support have guided me to making the right choices during the early stages of the company. Anthony is now our chairman and a vital part to our team, overseeing our structure and keeping us all on the right path as our business begins to grow.”

From moulding specialised motorsport parts to hand trimming and finishing composite components, Silverstone Composites strives to ensure quality workmanship throughout its production process to create products of the highest standards.

“In my experience, many composites suppliers tend to have a similar work ethic in that they are only really in the motorsport industry to make a lot of money on a short-term basis. Silverstone Composites is a completely different proposition: we pay our employees a good salary, aim to work a maximum of 40-50 hours a week, pay bonuses, offer good pension plans and we’ve structured our operations so that they are all process driven. We guarantee the best and we always deliver on-time.”

Kit and caboodle

Trofimov says the company is able to fabricate carbon fibre components which are strong, durable, lightweight, high-temperature-tolerant and show low thermal expansion. Silverstone Composites’ full list of capabilities includes: composite mould manufacturing, composite laminating, autoclave and oven curing, hand trimming and finishing, bonding and final assembly and inspection of components.

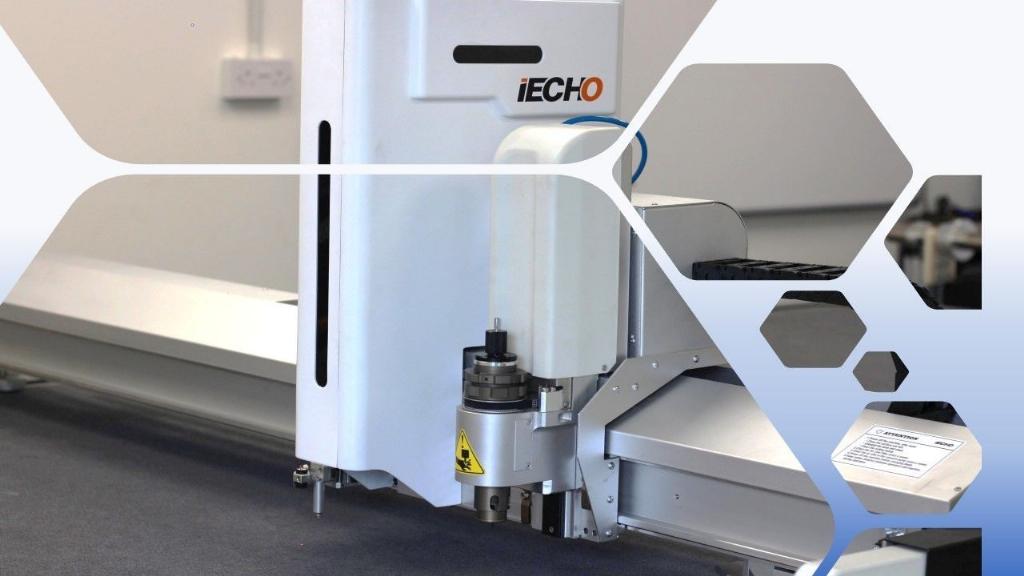

“We’ve recently taken delivery of an iEcho flatbed kit cutting machine, which we hope will make us around 30-40% more efficient because at present, we’re cutting everything by hand from template. We’ve started nesting all the kits and establishing parameters for the material on each type of project. For us as a smaller entity, the iEcho represents an ideal starter machine with which to learn and educate ourselves, and then as we grow and expand, we may look to towards purchasing a bigger and better machine. Our customers are welcome to send us their component dxf CAD files and we will cut the material and vacuum bag it.

“Elsewhere, our cleanroom has recently undergone expansion and now covers a full mezzanine area to contain wipe-down wall that help keep the area tidy. Next door, is our store room and beside that, our release agent room which contains an ESTA extraction system. In fact, we’ve spent a total of £20k on ESTA extraction equipment. We have a side- and down-draft bench system, plus overarm extraction systems in place too. Most trim shops can be fairly dusty environments, whereas we have an open room with hardly any dust at all because the quality levels of extraction are phenomenal. At any one time, we’ve probably got the best part of over 2000m2 of prepreg material stored in our walk-in freezer which has been supplied to us by multiple material suppliers around the UK.”

Going the extra mile

In terms of the types of demands placed on the company by today’s customers, Trofimov is keen to point out that his company is not just a build-to-print manufacturer – it is a problem-solver.

“There is a growing trend from our motorsport customers for answers to certain technical issues with where they need our input. We will assist them and look at the technologies that we have used or have purposefully seen, and propose our own processes and ideas to produce an end result and achieve a solution for the customer. This gives them a peace of mind, single solution to their problem and removes any headaches. From providing a solution, we hope to gain more work off the back of this in order to win more business and supply the component parts they need.

“The customer no longer has an in-house headache - instead, we deal with it and give them the final product to make the whole process as stress-free as possible. It’s been a huge learning curve: rather than just being a build-to-print supplier, we can provide some truly wonderful ideas and solutions by performing lots of research and development into new materials and production processes. It excites me even more than purely just building a part to a drawing and delivering it to the customer.”

Trofimov is looking to create a more feel-good, family-based feel where every customer is looked after, whatever their size. Silverstone Composite isn’t just chasing the big paying contracts; its smaller customers are just as important and valued. For him, it’s about maintaining this ethos – not just for his company, but for his suppliers as well.

“Without a great team behind me, I wouldn’t have a company, he concludes. “I want to give them some incentives; by working smarter, they can earn more for doing less, whilst the company continues to perform excellently and remain profitable. Our business model is completely different to many of the ‘copycat’ suppliers already in this industry. We thoroughly enjoy what we do and we ensure we offer the highest quality and deliver on-time, every time.”